Call us now

Showroom

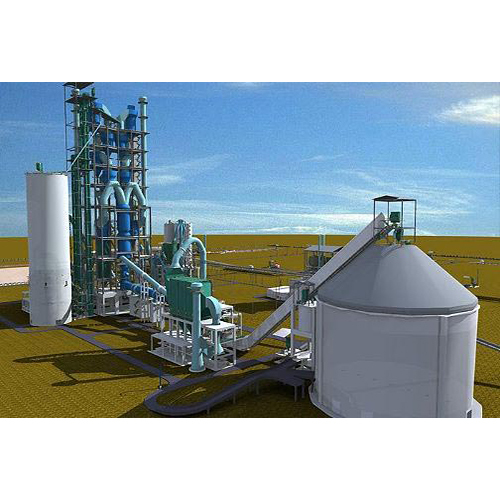

Ashoka Machine Tools Corporation is a trusted provider of cement plant machinery. Several industrial cement plant in this category like clinker grinding units, complete cement plant, cement plants- with vertical shaft kilns, etc., are provided in different ranges.

If you want to start your own sugar factory, the first step is to set-up a sugar plant. This plant carries out the entire work, right from cleaning sugarcane through to packing sugar in packaging materials.

Process Equipment is utilized in a variety of industries, including oil and gas, agricultural, mining, municipal, and manufacturing. Pumps, valves, vessels, filters, coolers, heat exchangers, pulsation dampeners, and pipes are some types of process equipment often used in these sectors. They are very easy to install and simple to operate.

Our company, Ashoka Machine Tools Corporation has qualified engineers for executing heavy fabrication works for medical, metal, food, chemical and more big industries. We supply custom storage silos & tanks, crane and equipment to these industries.

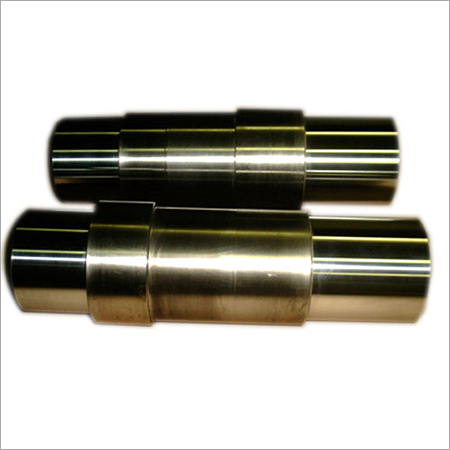

Gears, Pinions & Shafts of various sizes and types power the numerous machinery and equipment found in our companies and houses. They serve as a gear holding, bearing, synchromesh, and several other tasks. They require very low maintenance and replacement costs.

Our range of mill & kiln spares include ball mill, kiln shells, kiln support roller, kiln tyre, etc. These spares are available to our customers worldwide all year around, so that they do not face any problem in repair and maintenance work.

Our range of gears, pinions & shafts, like spur gear, kiln girth gear and bull gear, is made for industrial use. These simple to install and operate equipment have drive system and steady velocity ratio.

Get sugar mill parts, like sugar graders & hoppers, rotary mud filters, vacuum crystallizers and more from Ashoka Machine Tools Corporation. These are used mainly in fabrication, replacement and maintenance works.

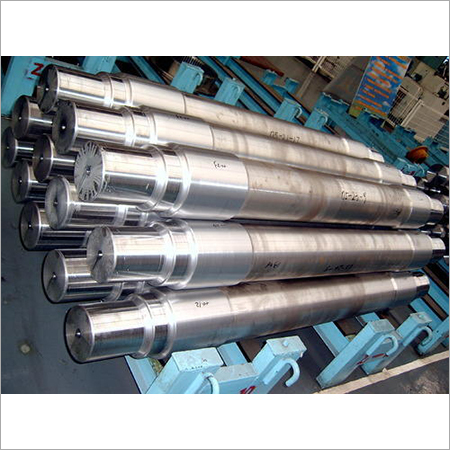

Wide ambit of Forged Products are being offered by us in the global market. These are rotating mechanical devices that can be rotated at different speeds to carry out diverse industrial processes. The products have tough structure owing to which can bear high temperature and pressure situations.

Ashoka Machine Tools Corporation presents industrial mill ends, for cement, dyeing, metal casting, mining and other heavy-duty industries. Tracer milling, profile milling, plunging and face milling are a few applications.

Highly efficient range of Industrial Shafts and Shaft Rolls is presented from our end to our valuable clients. These are utilized in mechanical equipment for transferring power from one part to the other one. The shafts and rolls can be availed in different diameters.

Project engineering consultation and turnkey erection and commissioning services are essential components of construction projects. A team of qualified and experienced professionals plan and execute the projects, while meeting the industry standards and specifications.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese