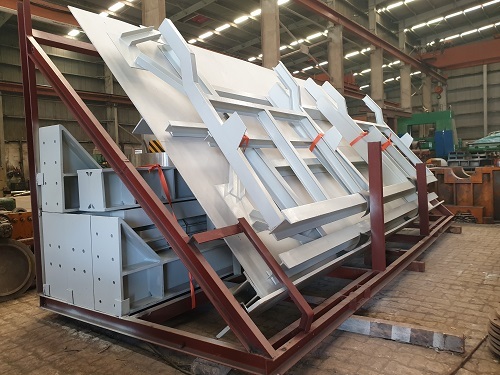

Structural Fabrication Work

Price 175 INR/ Kilograms

Structural Fabrication Work Specification

- Size

- As per requirement

- Protection Level

- Corrosion Resistant, Weather Resistant (

- Usage & Applications

- Construction, Industrial

- Surface Finish

- Sand Blasting, Grinding, Polishing

- Material

- Mild Steel, Carbon Steel, Stainless Steel, Alloy Steel

- Fabrication Service Type

- Heavy Fabrication Work

- Fabrication Product

- Structural Fabrication Work

- Fabrication Process

- Steel Frames, Beams, Columns, Trusses, Platforms, Support Structures

Structural Fabrication Work Trade Information

- Minimum Order Quantity

- 10 Metric Tons

- Payment Terms

- Cash in Advance (CID), Cheque, Cash Against Delivery (CAD), Letter of Credit at Sight (Sight L/C)

- Supply Ability

- 4 Metric Tons Per Month

- Delivery Time

- 15 Days

- Main Domestic Market

- All India

About Structural Fabrication Work

We manufacture and supply structural fabrication from various standardand non standard shapes and section steels including Girders, Angles, I-beams,C-Channels, Plates etc.

We fabricate complete plant outbuilding structures which are supplied aspre-fabricated structures.

The range of supply incorporates-

- Pre-fabricated shed constructions including rafters, box columns, purlins etc.

- Heavy crane supportive artifacts and platforms

- Machinery substructure and functional works

- Heavy duty supported frames works

- Storage tanks & silo fabrication

Heavy Structural Fabrication Work is tackled for assorted industrialspheres including-

- Mineral and ore processing plants

- Sugar plants and distilleries

- Steel plants

- Cement plants

- Power plants

- Lime kiln projects etc.

Materials

Different grades of steels as per national and international standards areemployed for Heavy Structural Fabrication Work. The plates and sections are oftime-tested quality from well established suppliers including Europeansuppliers. The grades of the steels utilized are-

- IS 2062 Grade A/B/C

- IS 2002 Grade I/II/III Boiler Quality

- ASME SA 516 Grade 60/65/70

- ASTM A 516 Grade 60/65/70

Rolling Capacity

- Up to 100 mm Th x 3500mm L on 3 roller rolling machine

Welding Technique

- MIG, TIG 2 mm to 8 mm electrodes, Submerged metal Arc

Welder Statement

- WPS Qualified (attested and sanctioned by third party inspection authority)

Weld Trials

- Radiography

- Ultrasonic testing

- Bend testing

- 100% on weld conjuncts

Lifting Capacity

- Elevated hook cranes up to 75 MT lifting capacity

- 2 Bays with 75 MT, 1 bay with 25 MT

Dynamic Equalization

- Up to 2500 mm diameter

- Sand Blasting

- Assembly size of 7000 mm x 7000 mm

- Stress Alleviating

- Furnace size of 4000 mm x 8000 mm

Some common steel grades we are making use of in offered structural workinclude :

|

IS 2062 Grade A/B/C |

IS 2002 Grade I/II/III Boiler Quality |

|

ASME SA 516 Grade 60/65/70 |

ASTM A 516 Grade 60/65/70 |

Technical Specifications:

|

Rolling Capacity |

Up to 100 mm Th x 3500mm L on 3 roller rolling machine |

|

Welding Technique |

Submerged metal Arc, MIG, TIG; 2 mm to 8 mm electrodes |

|

Welder Qualification |

WPS Qualified (attested and approved by third party inspection agency) |

|

Weld tests |

Radiography, Ultrasonic testing, Bend testing, 100% on weld joints |

|

Lifting Capacity |

Overhead hook cranes up to 75 MT lifting capacity, 2 Bays with 75 MT, 1 bay with 25 MT |

|

Dynamic Balancing |

Up to 2500 mm diameter |

|

Sand Blasting |

Chamber size of 7000 mm x 7000 mm |

|

Stress Relieving |

Furnace size of 4000 mm x 8000 mm |

Comprehensive Structural Solutions

Our structural fabrication work meets the requirements of both construction and industrial sectors. From steel frames and trusses to platforms and columns, every product is fabricated using high-quality materials with advanced protective finishes. These features guarantee resilience against corrosion and adverse weather, providing a dependable choice for infrastructure and manufacturing projects.

Precision Through Advanced Fabrication Processes

Fabrication involves modern methods for shaping and assembling steel into versatile structures. The use of sand blasting, grinding, and polishing ensures each component exhibits optimal surface finish and enhanced protection. Quality control at every stage secures the integrity and strength essential for building safety.

FAQs of Structural Fabrication Work:

Q: How is structural fabrication work utilized in construction and industrial projects?

A: Structural fabrication work serves as the foundation for buildings, factories, warehouses, and other large infrastructures. It includes components such as steel frames, beams, columns, and trusses, which provide support and stability in both construction and industrial applications.Q: What materials are commonly used in structural fabrication, and why?

A: Mild steel, carbon steel, stainless steel, and alloy steel are frequently employed due to their strength, durability, and adaptability. These materials are suitable for various fabrication needs and support high-resistance features, ensuring long-lasting performance.Q: When should corrosion- and weather-resistant finishes be applied during fabrication?

A: Corrosion- and weather-resistant finishes like sand blasting, grinding, and polishing should be applied after initial fabrication but before installation. This protects the steel structures from environmental damage, thus extending their service life.Q: Where can structural fabrication products from your company be used?

A: Our fabricated structural products are ideal for use in construction sites, manufacturing plants, warehouses, bridges, and other civil or industrial projects throughout India and international markets, owing to their robust quality and reliable protection.Q: What is the general process for manufacturing structural fabrication products?

A: The fabrication process involves designing, shaping, and assembling steel componentssuch as beams, columns, and platformsfollowed by finishing processes like sand blasting and polishing. Each step is conducted under strict quality control to maintain structural integrity.Q: How does surface finishing benefit fabricated steel structures?

A: Surface finishes, including sand blasting, grinding, and polishing, enhance the appearance and provide a protective layer that increases resistance to corrosion and adverse weather conditions. This ensures the structures have a longer operational life and reduced maintenance costs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heavy Fabrication Works Category

Custom Made Equipment Fabrication

Price 1000000 INR / Plant

Minimum Order Quantity : 1 Plant

Fabrication Product : Custom Made Equipment Fabrication

Fabrication Service Type : Heavy Fabrication Work

Protection Level : Corrosion Resistant, Heat Resistant, Wear Resistant

Size : As per requirement

Heavy Fabrication Work

Price 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Fabrication Product : Heavy Fabrication Work

Fabrication Service Type : Heavy Fabrication Work

Protection Level : Corrosion Resistant, Weatherproof

Size : 10 x5

Silos and Tank Fabrication

Minimum Order Quantity : 1 Plant

Fabrication Product : Silos and Tank Fabrication

Fabrication Service Type : Heavy Fabrication Work

Protection Level : Corrosion Resistant, Weather Resistant, Pressure Resistant

Size : As per requirement

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese