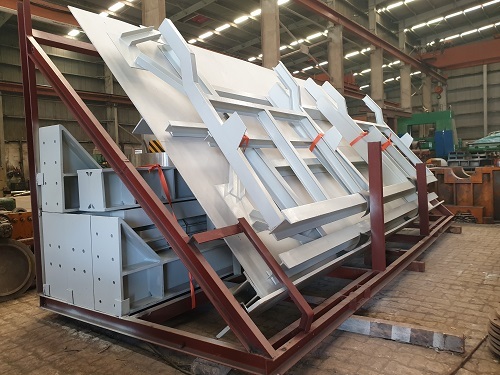

Heavy Fabrication Work

Price 500000 INR/ Piece

Heavy Fabrication Work Specification

- Coating Material

- Powder Coating, Epoxy Paint, Galvanizing

- Surface Finish

- Painted or Powder Coated

- Material

- Mild Steel, Carbon Steel, Stainless Steel

- Protection Level

- Corrosion Resistant, Weatherproof

- Usage & Applications

- Construction, Industrial

- Size

- 10 x5

- Fabrication Service Type

- Heavy Fabrication Work

- Fabrication Product

- Heavy Fabrication Work

- Fabrication Process

- Cutting, Welding, Machining, Bending,

Heavy Fabrication Work Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 4 Pieces Per Month

- Delivery Time

- 15 Days

About Heavy Fabrication Work

- Ppre-fabricated shed structures

- Heavy crane supporting structures and platforms

- Machinery supports and structural works

- Heavy duty base frames

- Storage tanks and silo fabrication

- Mineral and ore processing plants

- Cement plants

- Sugar plants

- Steel plants

- Power plants

- IS 2062 Grade A/B/C

- IS 2002 Grade I/II/III Boiler Quality

- ASME SA 516 Grade 60/65/70

- ASTM A 516 Grade 60/65/70

Comprehensive Fabrication Solutions for Industry

Our heavy fabrication services cater to construction and industrial sectors, prioritizing robust materials and advanced protection. Skilled techniques and precision coatings provide weatherproof and corrosion-resistant products designed for high-performance environments. Whatever your requirement, our expertise guarantees reliable steelwork tailored to challenging operational needs.

Advanced Protective Coatings for Extended Lifespan

Surface finishes such as powder coating, epoxy paint, and galvanization are integral to our fabrication process. These coatings safeguard assemblies against the effects of moisture, chemicals, and extreme temperatures. Clients benefit from longer-lasting, visually appealing components with minimal maintenance demands.

FAQs of Heavy Fabrication Work:

Q: How is heavy fabrication work carried out at your facility?

A: Our facility utilizes advanced cutting, welding, machining, and bending techniques. Each piece is manufactured with precision using mild steel, carbon steel, or stainless steel, followed by the application of durable surface finishes like powder coating, epoxy paint, or galvanizing.Q: What materials are used in your heavy fabrication products?

A: We primarily use mild steel, carbon steel, and stainless steel for heavy fabrication. These materials offer exceptional strength and are suitable for industrial and construction applications.Q: When should powder coating, epoxy paint, or galvanizing be chosen for surface protection?

A: Choice of surface protection depends on the operating environment. Powder coating and epoxy paint are ideal for aesthetically pleasing, corrosion-resistant finishes, while galvanizing offers enhanced protection where exposure to moisture and weathering is a concern.Q: Where can your fabricated products be used?

A: Our products are widely used in construction sites and industrial facilities, including factories, infrastructure projects, and heavy machinery assemblies. Their weatherproof and corrosion-resistant features make them suitable for challenging environments.Q: What is the typical process involved in heavy fabrication work?

A: The process starts with material selection, cutting, and shaping, followed by welding and machining. Bending forms complex shapes, and finally, protective coating is applied to ensure longevity and resistance to corrosion and weather.Q: How do clients benefit from your heavy fabrication solutions?

A: Clients receive reliable, high-strength products tailored to project needs. Our advanced coatings and material expertise minimize maintenance, extend lifespan, and deliver lasting value for industrial and construction applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heavy Fabrication Works Category

Structural Fabrication Work

Price 175 INR / Kilograms

Minimum Order Quantity : 10 Metric Tons

Surface Finish : Sand Blasting, Grinding, Polishing

Fabrication Process : Steel Frames, Beams, Columns, Trusses, Platforms, Support Structures

Fabrication Service Type : Heavy Fabrication Work

Usage & Applications : Construction, Industrial

Custom Made Equipment Fabrication

Price 1000000 INR / Plant

Minimum Order Quantity : 1 Plant

Surface Finish : Polished, Brushed, Sandblasted

Fabrication Process : Cutting, Welding, Machining, Bending,

Fabrication Service Type : Heavy Fabrication Work

Usage & Applications : Construction, Industrial

Silos and Tank Fabrication

Minimum Order Quantity : 1 Plant

Surface Finish : Sand Blasting, Polishing, Painting, Epoxy Coating

Fabrication Process : Cutting, Rolling, Welding, Assembly, Surface Treatment

Fabrication Service Type : Heavy Fabrication Work

Usage & Applications : Food Processing, Chemical Industry, Water Treatment

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese