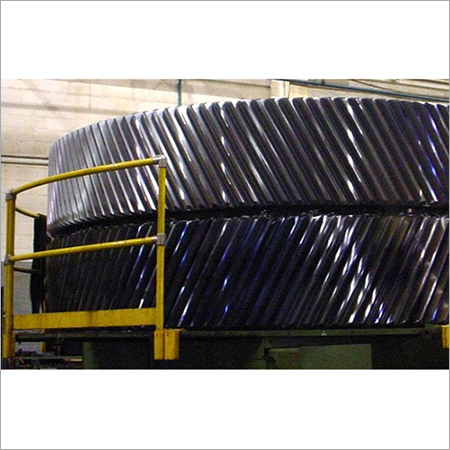

Herringbone Gear

Price 100000 INR/ Piece

Herringbone Gear Specification

- Surface Treatment

- Polished

- Machine Type

- Gear Hobbing / Gear Grinding / CNC Lathe

- Accessories Type

- Couplings, Shafts, Bearing

- Usage

- Industrial

- Type

- Herringbone Gear

- Material

- Metals/Plastics

- Size

- different sizes and grades as per requirements.

- Product Type

- Herringbone Gear

- Color

- Black

- Application

- Heavy duty industries

Herringbone Gear Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 4 Pieces Per Month

- Delivery Time

- 15 Days

About Herringbone Gear

- Application: Heavy duty industries

- Standards: ASTM & AISI, BS, JIS, GS, IS

- Material: Metals/Plastics

Robust Design for Industrial Performance

Herringbone gears excel in demanding industrial settings, thanks to their unique tooth configuration which distributes load evenly and minimizes vibration. Whether constructed from metals or advanced plastics, these gears deliver optimal strength and longevity, making them ideal for sectors like mining, manufacturing, and power generation.

Advanced Manufacturing Techniques

Utilizing gear hobbing, gear grinding, and CNC lathe machinery ensures herringbone gears maintain exacting tolerances and a polished finish. This sophisticated process guarantees gears operate efficiently and are well-suited for integration with other machine components including couplings, shafts, and bearings.

FAQs of Herringbone Gear:

Q: How are herringbone gears manufactured for industrial use?

A: Herringbone gears are produced using advanced gear hobbing, gear grinding, and CNC lathe machines, ensuring precise tooth alignment and a polished surface suitable for heavy-duty industrial environments.Q: What materials are commonly used to make herringbone gears?

A: These gears are primarily manufactured from durable metals or engineering-grade plastics, selected based on the applications load requirements and operating conditions in heavy-duty industries.Q: When should herringbone gears be chosen over other gear types?

A: Herringbone gears are best utilized when smooth, vibration-free power transmission is essential, particularly in applications involving high loads and continuous operation such as industrial machinery.Q: Where are herringbone gears most commonly applied?

A: They are widely used in heavy-duty industries, including mining, manufacturing, and power plants, where robust and efficient gear systems are needed for demanding mechanical tasks.Q: What is the process of installing herringbone gears with accessories like couplings and shafts?

A: Installation involves aligning the standard-sized herringbone gear with compatible couplings, shafts, or bearings to ensure seamless integration and optimal performance within the machinery.Q: How does the polished surface benefit herringbone gear usage?

A: The polished surface enhances durability, reduces friction, and contributes to smoother gear operation, minimizing wear and extending the gears service life in industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Gears Category

Precision Gears

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Precision Gears

Accessories Type : Bearings, Precision Shafts, Couplings

Material : steel

Application : Railway Industry

Worm Wheels

Minimum Order Quantity : 1 Plant

Type : Worm Wheels

Accessories Type : Bearings, Shafts, Bushings

Material : steel

Application : used in automobile, heavy duty and aerospace application

Helical Gears

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Helical Gears

Accessories Type : Shafts, Bearings, Couplings

Material : MS, Alloy steel Carbon Steel

Application : Gearboxes, Automotive Transmissions, Elevators, Conveyors

Pinion Gear

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Pinion Gear

Accessories Type : Shaft, Bearings, Coupling

Material : steel

Application : Gearboxes, Automotive Differentials, Machine Tools, Conveyor Systems

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese