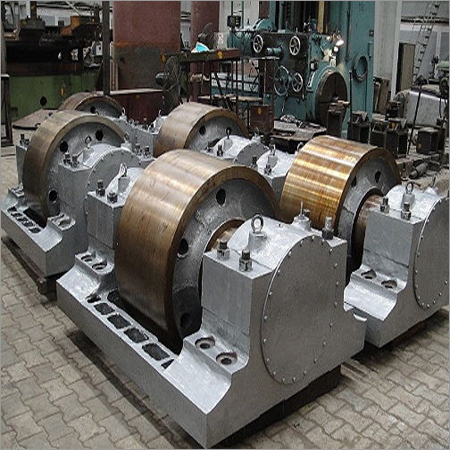

Ball Mill Headers

Price 200000 INR/ Plant

Ball Mill Headers Specification

- Drive Type

- Three Phase AC 440 V

- Usage & Applications

- Ball Mills, Rod Mills

- Features

- High Strength, Wear Resistant, Precision Tooth Profile

- Size

- 3.0 m height

- Surface Finish

- Polished

- Diameter

- Up to 6.0 m flange diameter Meter (m)

- Product Type

- Machine Accessories

- Material

- Steel

- Technology

- CNC

- Power Source

- Electricity

- Surface Treatment

- Painted

- Color

- Sliver

- Warranty

- 1 Year

Ball Mill Headers Trade Information

- Minimum Order Quantity

- 1 Plant

- Supply Ability

- 100 Plants Per Month

- Delivery Time

- 1 Months

About Ball Mill Headers

We at Ashoka manufacture an excellent range of mill headers with standard thickness and quality. We can also customize them as per the clients application requirements. These are used a lot in metal casting, mining, cement, and also in dyeing industries. It is perfect for a continuous process to raise the temperature of the material, especially for heavy duty industries. Precision-engineered our mill headers are widely acclaimed for their dimensional accuracy, trouble free operation and less maintenance.

Established in the year 1968, we have concentrated all our efforts to meet the Ball Mill Headers related requirements of various industries in the best possible manner. These headers are manufactured by using quality test material and advance technology in accordance with international quality standards. Our products are perfect for raising the temperature of the material in a continuous process in cement, mining, metal casting and dyeing industries

|

Capacity |

Size |

Common Applications |

|

Suitable for ball mills up to 5.0 m shell diameter |

Up to 6.0 m flange diameter and 3.0 m height, |

Ball Mills, Rod Mills |

-

Ideal for ball mills up to 5.0 m shell diameter

- 3.0 m height

- Max weight up to 50MT single piece

- Up to 6.0 m flange diameter

- Rod Mills

- Ball Mills

Durable Construction

Crafted from high-strength steel, Ball Mill Headers are designed to endure rigorous operating conditions. The polished surface combined with advanced painting offers enhanced resistance to corrosion, ensuring prolonged lifespan and consistent performance in demanding industrial environments.

Advanced Engineering Precision

Utilizing CNC machining, each header maintains precise tooth profiles for optimal alignment and smooth operation within ball mills. This technological advancement results in minimal wear, reduced maintenance needs, and superior reliability during continuous industrial use.

Versatile Applications

Ball Mill Headers cater to varied applications within industrial processing plants, mineral grinding, cement production, and other heavy-duty sectors. Supplied across India, their versatility makes them suitable for new installations and retrofit solutions alike, supporting both manufacturers and exporters.

FAQs of Ball Mill Headers:

Q: How are Ball Mill Headers used in industrial applications?

A: Ball Mill Headers serve as crucial components in ball milling machines, facilitating the entry and exit of materials during the grinding process. Their robust design allows for efficient and reliable operation in various industrial settings, including mineral processing and cement plants.Q: What materials and technologies are used in manufacturing Ball Mill Headers?

A: The headers are fabricated from high-strength steel, utilizing advanced CNC technology for precision tooth profiling and optimal surface finish. A combination of polished and painted surfaces enhances durability, wear resistance, and aesthetic appeal.Q: When should Ball Mill Headers be replaced or serviced?

A: Replacement or servicing is recommended when there are visible signs of wear, a decline in operational efficiency, or at the end of the warranty period, which is one year. Regular inspection in line with manufacturer guidelines helps ensure continuity and prevent unexpected downtime.Q: Where can Ball Mill Headers be sourced in India?

A: Ball Mill Headers are available from trusted exporters, manufacturers, and suppliers across India, offering both domestic and international distribution to meet industry requirements.Q: What benefits do precision tooth profiles and polished surfaces provide?

A: Precision tooth profiles ensure accurate alignment and smooth movement within the ball mill, improving grinding efficacy. The polished, painted surface offers resistance to wear and corrosion, resulting in reduced maintenance costs and longer service life.Q: How does the warranty and after-sales support work?

A: Ball Mill Headers come with a one-year warranty covering manufacturing defects. Manufacturers and suppliers in India also provide after-sales support, assisting with installation guidance, maintenance, and replacement needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mill & Kiln Spares Category

Kiln Tyre

Price 100000 INR / Plant

Minimum Order Quantity : 1 Plant

Drive Type : Three Phase AC 440 V

Product Type : Machine Accessories

Material : Steel

Usage & Applications : usage in cement, metal casting, mining and dyeing industries.

Kiln Support Roller

Price 100000 INR / Plant

Minimum Order Quantity : 1 Plant

Drive Type : Electric

Product Type : Machine Accessories

Material : Cast and forged alloy steels

Usage & Applications : used in various mills for proper and hassle free functioning

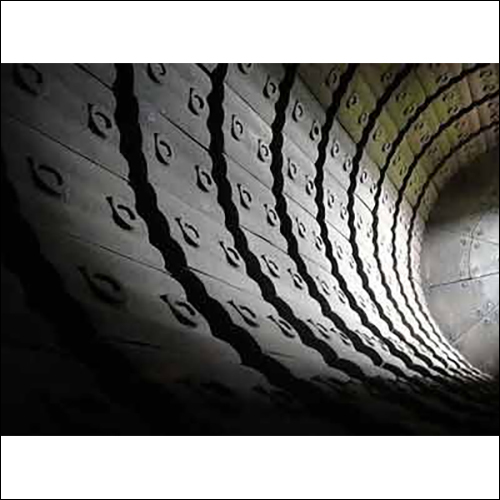

Ball Mill Liners

Price 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Drive Type : Three Phase AC 440 V

Product Type : Machine Parts

Material : Stainless Steel

Usage & Applications : Cement,Mining, Metal casting, Dyeing

Kiln Shells

Price 200000 INR / Plant

Minimum Order Quantity : 1 Plant

Drive Type : Electric

Product Type : Machine Parts

Material : Stainless Steel

Usage & Applications : used during the production process of metals, construction materials, sponge iron, chemicals, cement, refractories, petroleum and gypsum

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese