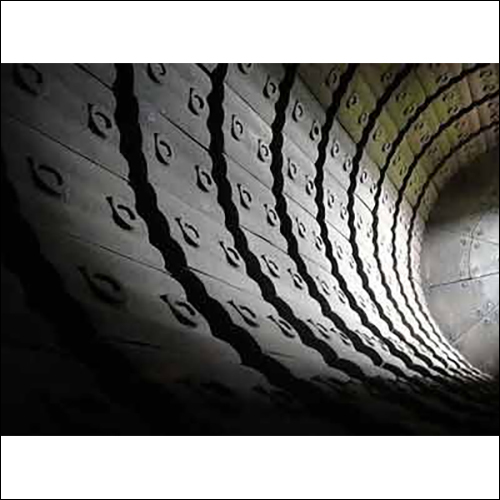

Ball Mill Liners

Price 500000 INR/ Piece

Ball Mill Liners Specification

- Usage & Applications

- Cement,Mining, Metal casting, Dyeing

- Shape

- Customized

- Surface Finish

- Smooth

- Size

- Customized

- Features

- High Strength, Wear Resistant, Precision Tooth Profile

- Drive Type

- Three Phase AC 440 V

- Product Type

- Machine Parts

- Material

- Stainless Steel

- Technology

- CNC

- Power Source

- Electricity

- Voltage

- 380-440 Volt (v)

- Surface Treatment

- Painted

- Color

- Gray

- Warranty

- 1 Year

Ball Mill Liners Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 4 Pieces Per Month

- Delivery Time

- 15 Days

About Ball Mill Liners

- The ball mill liners find use in heavy duty industries to rise temperatures of material in continuous process.

- Overall kiln size on the basis of process conditions and can be different in regards to diameter and length.

- Alignment tabs at shop sections are welded inside shell and find application in holding and aligning shell pieces during final welding.

- Cement

- Mining

- Metal casting

- Dyeing

Custom-Fit Precision Engineering

Our ball mill liners are customized to match your unique size and shape requirements, guaranteeing an optimal fit and efficient operation within your industrial processes. Precision CNC technology ensures every liner meets stringent quality standards for smoothness and tooth profile.

Enhanced Durability and Wear Resistance

Made from robust stainless steel and treated surfaces, these liners resist corrosion and abrasion, making them ideal for prolonged use in harsh industrial environments. Their high strength markedly improves mill longevity and reduces the need for frequent replacements.

Reliable Supplier Across India

As a leading exporter, manufacturer, and supplier in India, we deliver expertly engineered ball mill liners nationwide. Our comprehensive service includes custom solutions, swift delivery, and one-year warranty support for peace of mind.

FAQs of Ball Mill Liners:

Q: How are the ball mill liners customized to fit specific industrial requirements?

A: Our liners are manufactured using advanced CNC technology to meet the exact size and shape specifications provided by customers. This ensures a precise fit for various industrial milling machines and maximizes grinding efficiency.Q: What benefits does stainless steel material provide for ball mill liners?

A: Stainless steel offers exceptional strength, corrosion resistance, and wear resistance, resulting in extended liner life and consistent performance even in demanding industrial conditions.Q: When should ball mill liners be replaced?

A: Ball mill liners should be replaced when signs of significant wear or reduced grinding efficiency appear. With high-strength stainless steel and wear-resistant properties, our liners typically have a longer service lifespan, reducing the frequency of replacements.Q: Where are your ball mill liners primarily used?

A: These liners are widely used in industrial grinding and milling applications, including cement, mining, and various manufacturing sectors where durability and efficient processing are essential.Q: What is the process for ordering customized ball mill liners?

A: Customers can provide their specific requirements regarding size, shape, and application. Our team then fabricates the liners using CNC technology, applies a painted smooth surface finish, and delivers the customized product along with warranty support.Q: How does the smooth surface finish contribute to milling operations?

A: The carefully painted and smooth surface finish reduces friction and improves material flow, consequently enhancing the grinding process while minimizing liner and mill wear.Q: What advantages do precision tooth profiles offer in ball mill liners?

A: Precision tooth profiles, achieved through CNC machining, enable uniform grinding, efficient material movement, and reduced energy consumption, ultimately boosting milling productivity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mill & Kiln Spares Category

Kiln Tyre

Price 100000 INR / Plant

Minimum Order Quantity : 1 Plant

Features : Heavy Duty

Surface Finish : Polished

Product Type : Machine Accessories

Drive Type : Three Phase AC 440 V

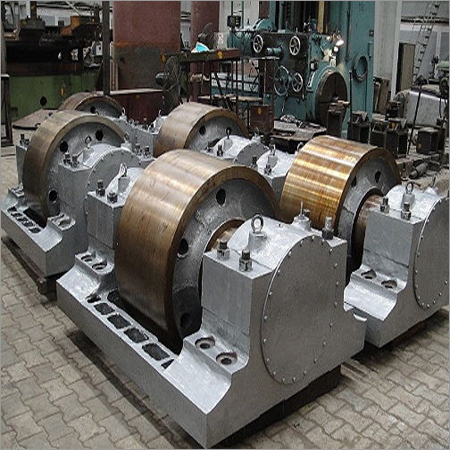

Kiln Support Roller

Price 100000 INR / Plant

Minimum Order Quantity : 1 Plant

Features : High load capacity, long service life, precision engineered, wear resistant

Surface Finish : Smooth, Machined, AntiCorrosive

Product Type : Machine Accessories

Drive Type : Electric

Ball Mill Headers

Price 200000 INR / Plant

Minimum Order Quantity : 1 Plant

Features : High Strength, Wear Resistant, Precision Tooth Profile

Surface Finish : Polished

Product Type : Machine Accessories

Drive Type : Three Phase AC 440 V

Kiln Shells

Price 200000 INR / Plant

Minimum Order Quantity : 1 Plant

Features : High Strength, Wear Resistant, Precision Tooth Profile

Surface Finish : Polished

Product Type : Machine Parts

Drive Type : Electric

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese