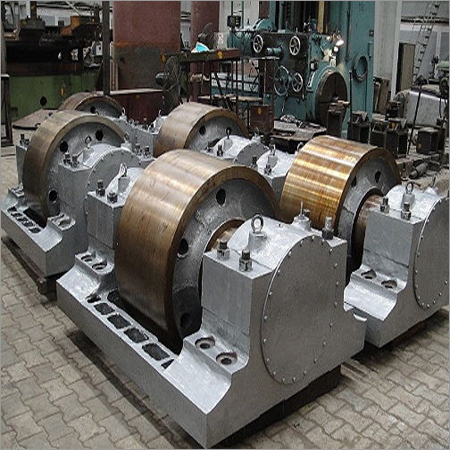

Kiln Support Roller

Price 100000 INR/ Plant

Kiln Support Roller Specification

- Surface Finish

- Smooth, Machined, Anti-Corrosive

- Features

- High load capacity, long service life, precision engineered, wear resistant

- Drive Type

- Electric

- Usage & Applications

- used in various mills for proper and hassle free functioning

- Noise Level

- Less than 80 db

- Capacity

- 100-300 Kg/hr

- Diameter

- 300 - 2000 Millimeter (mm)

- Product Type

- Machine Accessories

- Material

- Cast and forged alloy steels

- Technology

- Precision

- Power Source

- Electricity

- Voltage

- 220/380 Volt (v)

- Weight

- 1000 to 2500 Kilograms (kg)

- Color

- Sliver

Kiln Support Roller Trade Information

- Minimum Order Quantity

- 1 Plant

- Supply Ability

- 100 Plants Per Month

- Delivery Time

- 1 Months

About Kiln Support Roller

Precision Engineering for Industrial Efficiency

Each kiln support roller is crafted with advanced precision technology, ensuring consistent performance even under heavy loads. The use of premium cast and forged alloy steels guarantees reliability in continuous operations, making these rollers a critical component for efficient and stable rotary kiln functioning in the industrial sector.

Superior Features for Longevity and Performance

Designed for optimal durability, the rollers feature a smooth, anti-corrosive surface and exhibit excellent wear resistance. Their high load capacity combined with long service life leads to reduced downtime and maintenance costs, benefiting manufacturers and process operators across diverse industrial applications.

FAQs of Kiln Support Roller:

Q: How are kiln support rollers installed in industrial settings?

A: Kiln support rollers are typically installed as foundational supports for rotary kilns in industrial plants. The precise machining and robust materials allow them to be aligned accurately with the kiln shell, ensuring smooth rotation and stability during operation.Q: What materials are used to manufacture these support rollers?

A: These rollers are constructed from cast and forged alloy steels, selected for their strength, durability, and ability to withstand intense operational demands in industrial environments.Q: When should a kiln support roller be replaced or serviced?

A: Regular inspection is recommended, but replacement or servicing should occur when significant wear, misalignment, or surface damage is observed, which can affect the rollers load capacity and kiln stability.Q: Where are these kiln support rollers commonly used?

A: They are widely utilized in cement manufacturing, mineral processing, and other heavy-duty industrial sectors where rotary kilns play a key role in production processes.Q: What is the process of manufacturing a kiln support roller?

A: Manufacturing involves casting and forging alloy steels, followed by precision machining and anti-corrosive treatment. Each roller is then finished to specific diameter and weight requirements and tested for quality and performance.Q: How does using a precision-engineered support roller benefit industrial operations?

A: Precision-engineered support rollers ensure stable kiln rotation, improved load distribution, lower maintenance frequency, and increased operational lifespan, ultimately boosting overall plant efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mill & Kiln Spares Category

Kiln Tyre

Price 100000 INR / Plant

Minimum Order Quantity : 1 Plant

Usage & Applications : usage in cement, metal casting, mining and dyeing industries.

Surface Treatment : Coated

Product Type : Machine Accessories

Drive Type : Three Phase AC 440 V

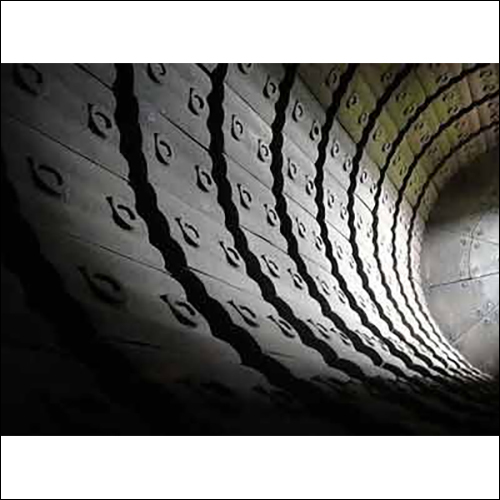

Ball Mill Liners

Price 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage & Applications : Cement,Mining, Metal casting, Dyeing

Surface Treatment : Painted

Product Type : Machine Parts

Drive Type : Three Phase AC 440 V

Ball Mill Headers

Price 200000 INR / Plant

Minimum Order Quantity : 1 Plant

Usage & Applications : Ball Mills, Rod Mills

Surface Treatment : Painted

Product Type : Machine Accessories

Drive Type : Three Phase AC 440 V

Kiln Shells

Price 200000 INR / Plant

Minimum Order Quantity : 1 Plant

Usage & Applications : used during the production process of metals, construction materials, sponge iron, chemicals, cement, refractories, petroleum and gypsum

Surface Treatment : Painted

Product Type : Machine Parts

Drive Type : Electric

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese