Project Engineering Consultation

MOQ : 1 Piece

Project Engineering Consultation Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 4 Pieces Per Month

- Delivery Time

- 15 Days

About Project Engineering Consultation

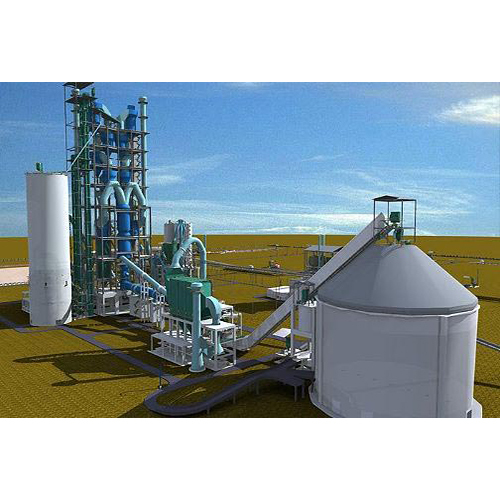

Design Engineering

The plants design is optimized in order to allow for capacity optimization, energy efficient boiling and minimum steam consumption. Exclusive design software, including Autocad, Pro engineer, solid works along with technical documents are utilized in project engineering. Together with civil designs and drawings, this job also includes plant and site layouts, equipment and sectional general arrangements, equipment specifications and data sheets, steam and power balances, piping and electrical work.

Having a rich history and a promising future, Ashoka Machine Tools Corporation looks forward with confidence to the future. Emphasis is given to find an economically competent design while keeping in mind the working conditions and cost structure of the project.

Turnkey Erection And Commissioning

Ashoka Machine Tools Corporation is a reliable name for buying automated and energy efficient sugar plants and sugar refineries. The designing process involves the use of sophisticated and future perfected user-friendly technologies that are included as per the Turnkey Project Management. Plants are customized to meet requirements of clients as per the local condition and logistics. The project management team makes sure that they complete each project on time.

Efficient Automation Solutions

Our consultations deliver turnkey solutions for fully automatic, electrically-driven projects, using AC motors and fly ash materials. We combine engineering expertise with advanced automation to help businesses achieve higher productivity, consistency, and reduced operational costs. Whether you need customized designs or process upgrades, our team ensures your systems meet international standards.

Expert Support for Project Success

From initial analysis to commissioning, our experienced professionals guide clients through each stage of project development. We facilitate smooth transitions from manual to fully automatic production, selecting optimal materials and technologies suited for industrial environments. Our consultative process ensures that your engineering investments yield tangible improvements and reliable long-term performance.

FAQs of Project Engineering Consultation:

Q: How does your project engineering consultation benefit industrial automation projects?

A: Our consultation services optimize production processes by integrating fully automatic systems with electric drive types and AC motors. This boosts efficiency, reduces manual intervention, and enhances overall productivity using fly ash materials, resulting in cost-effective and sustainable solutions.Q: What is involved in the process of implementing a fully automatic system with your consultation?

A: The process typically includes requirements assessment, design planning, selection of equipment such as electric drive AC motors, material evaluation (fly ash), and supervised installation. Our team ensures thorough project management and system integration for seamless operation.Q: When should companies seek project engineering consultation for fly ash-based automation?

A: Companies should consider consulting at the planning or modernization stage of their production line, especially when transitioning to fully automatic electric systems or expanding operations with new materials like fly ash.Q: Where do you provide your consultation and engineering services?

A: We are based in India and serve a broad spectrum of clients nationwide. Additionally, as exporters, we offer consultation and engineering support to international clients, ensuring high standards and reliable service globally.Q: How does using a fully automatic system with AC motors improve production usage and output?

A: Fully automatic systems driven by AC motors offer precise control, consistent operation, and minimized downtime. This increases output quality and process reliability, especially when working with fly ash as the primary material.Q: What are the key benefits of sourcing project engineering consultation from an Indian exporter, manufacturer, and supplier?

A: Sourcing from an Indian exporter and manufacturer ensures competitive pricing, access to advanced technologies, and comprehensive support. Clients benefit from tailored solutions, robust quality assurance, and reliable after-sales service.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Construction Projects Category

Turnkey Erection and Commissioning

Minimum Order Quantity : 1 Piece

Product Type : Turnkey Erection and Commissioning

Automatic : Yes

Automatic Grade : Semi Automatic

Drive Type : Electric

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese