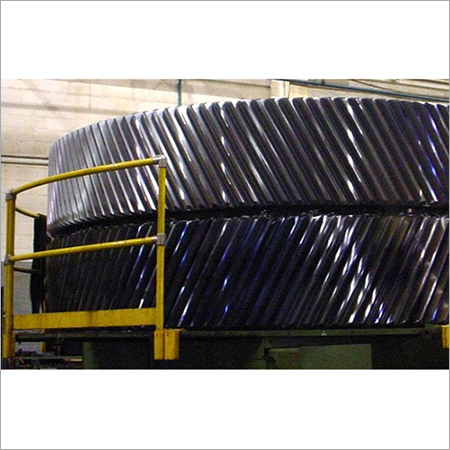

Spur Gears

Price 100000 INR/ Piece

Spur Gears Specification

- Machine Type

- Gear Hobbing Machine / Gear Shaping / CNC Lathe

- Features

- High Efficiency, Simple Design, Easy to Manufacture, Cost-Effective

- Automation Grade

- Automatic

- Accessories Type

- Bushings, Bearings, Shafts

- Technology

- CNC Machining, Gear Hobbing, Gear Shaping,

- Surface Treatment

- Polished

- Type

- Spur Gears

- Material

- steel

- Color

- Sliver

- Application

- Gear boxes machines, mining equipments, material handling equipments and gear pump units

Spur Gears Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 4 Pieces Per Month

- Delivery Time

- 15 Days

About Spur Gears

We are exporter and manufacturer of Spur Gears mainly in countries Philippines, United States, Tanzania, Australia, Egypt, Argentina, Bolivia, Thailand, Ethiopia, Indonesia, Libya, Kenya, United Kingdom, Zambia etc. We are exporting this product to fulfill our buyers requirement on regular basis.

Being a pioneer in the current industry, we are engaged in manufacturing, exporting and providing service for Spur Gears. Considered as a common type of gears, these are appreciated as a gearwheel that comprises of teeth projection, paralleled to the wheels axis. Our provided assortment is enclosed around a central axle and comprises of one or more screwed thread performing as their teeth. Hence, our products are well praised among our valued patrons due to their unmatched attributes and producing excellent transmission where rotational speed is required.

Features ofSpur Gears

- Finished surface

- Rust proof design

-

Minimizes vibration

- High power transmission efficiency.

- Simple and also easy to design

- Power transmission efficiency in case of spur gear driving system will be quite good

- Constant velocity ratio

- Spur gears are quite more efficient as compared to helical gear

- Spur gears are highly reliable

-

Transmit large amount of power (of the order of 50,000 kW)

- Power plants

- Washing Machines

- Automobile gear boxes

- Metal cutting machines

- Steel mills

- Marine engines

- Rack and pinion mechanisms

- Mechanical clocks and watches

- Fuel pumps

- Gear motors and gear pumps

- Material handling equipments

- Rolling mills

High-Performance Spur Gears for Industrial Automation

Our industrial-grade spur gears are expertly engineered for optimal performance in gearboxes, mining equipment, and more. Utilizing CNC machining and gear hobbing, each gear features a polished silver surface for enhanced durability and efficiency. Designed for integration with automatic machine systems, these gears are suitable for robust, long-term industrial use.

Simple Design and Reliable Manufacturing

Manufactured in India using sophisticated gear shaping and hobbing methods, our spur gears boast an uncomplicated yet effective design. This simplicity enables straightforward installation, low maintenance, and yields a cost-effective solution for a wide range of industrial material handling applications.

FAQs of Spur Gears:

Q: How are Spur Gears manufactured for industrial applications?

A: Spur gears are produced using advanced CNC machining, gear hobbing, and gear shaping techniques to ensure precision and consistent quality. These processes help achieve the ideal tooth profiles and polished surfaces required for demanding industrial operations.Q: What are the main benefits of using steel spur gears in gearboxes and mining equipment?

A: Steel spur gears deliver excellent efficiency, durability, and resistance to wear. Their simple, cost-effective design translates to efficient power transmission, high reliability, and easy integration into gearboxes, mining machines, and other industrial systems.Q: When should polished steel spur gears be chosen for automated machinery?

A: Polished steel spur gears are recommended when your application requires high efficiency, smooth operation, low maintenance, and extended lifespan. Their automatic grade makes them suitable for gear hobbing machines, CNC lathes, and automated gear shaping systems.Q: Where are these spur gears commonly used?

A: These spur gears are widely employed in gearboxes, mining equipment, material handling systems, and gear pump units. Their robust construction and precision machining make them ideal for heavy-duty industrial environments.Q: What is the process for integrating spur gears with accessories like bushings and shafts?

A: Integration typically involves matching the gears with suitable bushings, bearings, and shafts designed for your machinery. This ensures proper alignment, smooth operation, and extends the lifespan of the entire drivetrain system.Q: How does the surface treatment enhance gear performance?

A: The polished surface treatment minimizes friction, reduces wear and corrosion, and contributes to a smoother, more efficient transfer of power within industrial equipment.Q: What makes these gears cost-effective for industrial suppliers and manufacturers?

A: Their simple design, ease of manufacture, and reliable performance ensure lower production and maintenance costs, making them a practical choice for industrial suppliers, manufacturers, and exporters operating in India.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Gears Category

Kiln Gear

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Accessories Type : Couplings, Bear'ings, Lubrication Systems

Application : Ball mills, rod mills, rotary kilns, rotary coolers, crusher mills, mining, steel plants, power plants, paper plants, fertilizer plants, grinding applications, heavy machinery etc.

Material : steel

Type : Kiln Gear

Herringbone Gear

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Accessories Type : Couplings, Shafts, Bearing

Application : Heavy duty industries

Material : Metals/Plastics

Type : Herringbone Gear

Mill Gears

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Accessories Type : Shafts, Couplings, Bearings, Gearboxes

Application : Mill Girth Gears expertly designed for industrial applications like steel rerolling mills, paper industries, and sugar mills.

Material : steel

Type : Mill Gears

Helical Gears

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Accessories Type : Shafts, Bearings, Couplings

Application : Gearboxes, Automotive Transmissions, Elevators, Conveyors

Material : MS, Alloy steel Carbon Steel

Type : Helical Gears

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese