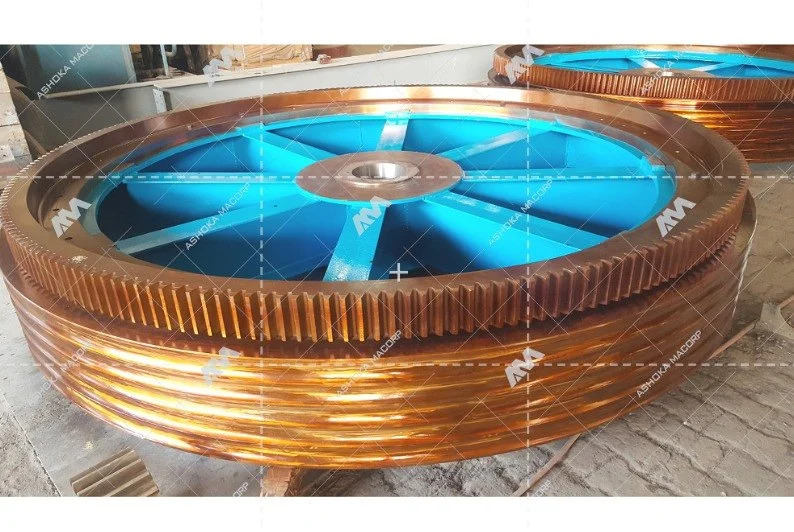

Kiln Gear

Price 300000 INR/ Piece

Kiln Gear Specification

- Technology

- Precision Casting, CNC Machining, Heat Treatment

- Surface Treatment

- Case Hardened, Shot Peening, Phosphate Coating

- Automation Grade

- Automatic

- Machine Type

- Rotary Kiln Drive Systems

- Accessories Type

- Couplings, Bear'ings, Lubrication Systems

- Usage

- Ball mills, rod mills, rotary kilns, rotary coolers, dryers for cement plants, power plants, steel plants, mineral grinding & processing plants etc.

- Type

- Kiln Gear

- Material

- steel

- Product Type

- Kiln Gear

- Color

- Green

- Application

- Ball mills, rod mills, rotary kilns, rotary coolers, crusher mills, mining, steel plants, power plants, paper plants, fertilizer plants, grinding applications, heavy machinery etc.

Kiln Gear Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 4 Pieces Per Month

- Delivery Time

- 15 Months

About Kiln Gear

We are exporter and manufacturer of Kiln Gear mainly in countries Philippines, United States,Tanzania, Australia, Egypt, Argentina, Bolivia, Thailand, Ethiopia, Indonesia, Libya, Kenya, United Kingdom, Zambia etc. We are exporting this product to fulfill our buyers requirement on regular basis .

Contact or email for best Kiln Gear at best rate .

|

Type |

Machining Capacity |

Application |

|

Split / Girth Gears Ring Gears |

8.5 m Dia x 50 Module |

Ball mills, rod mills, rotary kilns, rotary coolers, dryers for cement plants, |

|

Sugar Mill Gears |

8.5 m Dia x 50 Module |

Crusher mills, crush rolls for sugar plants |

|

Fabricated Gears |

5.0 m Dia x 50 Module |

Ball mills, rod mills, rotary kilns, rotary coolers, crusher mills, mining, steel plants, |

|

Worm Gears |

4.0 m Dia x 40 Module |

Gear reducers, open gearing for various industrial sectors specified above |

|

Ground Gears |

1.9 m Dia x 30 Module |

Gear reducers, machine tools and various other applications for above specified |

Types of heat treatments offered:

- Volume Hardening

- Induction Hardening

- Stress Relieving

- Case Carburizing

- Nitriding

The tasks of gear inspection are carried out by using special hand, automatic instruments, mechanical instruments and testers manufactured by well-known companies like MITOTOYO etc. Various tests cover material tests like mechanical testing and hardness testing, chemical testing, and dimensional measurements. Also, we perform non destructive testing for internal flaws which includes magnetic particle inspections (MPI) and ultrasonic testing (UST). Moreover, developer penetrant testing (DP) is executed for surface crack detection. Gear tooth profiles are tested with special instruments such as profiles testers and vernier calibres.

We provide life-time after sales technical support to our industrial customers for all our supplied gears and pinions. The support covers services that help to smooth the work process, and on-site support is rendered on chargeable basis.

Precision Engineering for Reliable Performance

Our kiln gear undergoes precision casting and CNC machining, ensuring tight tolerances and optimal fit for rotary kiln drive systems. Supported by thorough heat treatment, the gear maintains structural integrity even under demanding industrial operations, making it an ideal choice for continuous, automated systems.

Enhanced Durability with Advanced Surface Treatments

The gear receives comprehensive surface treatments, such as case hardening, shot peening, and phosphate coating, which collectively improve its strength and resistance to abrasion. These processes reduce maintenance frequency, extending the equipments lifecycle and ensuring consistent performance.

FAQs of Kiln Gear:

Q: How is the kiln gear manufactured to ensure high performance?

A: The kiln gear is manufactured using precision casting and CNC machining followed by heat treatment. These processes guarantee dimensional accuracy, superior strength, and reliability for heavy-duty industrial applications.Q: What surface treatments are applied to the kiln gear and how do they benefit its usage?

A: Case hardening, shot peening, and phosphate coating are applied to the kiln gear. These treatments significantly improve abrasion resistance, minimize wear, and extend operational lifespan, especially in continuous rotary kiln drive systems.Q: When should the kiln gear be used in industrial machinery?

A: The kiln gear is ideal for use in rotary kiln drive systems during applications that demand precise, automated, and reliable motion transfer in industries such as cement, metallurgy, and chemical processing.Q: Where is this kiln gear produced and exported from?

A: This kiln gear is manufactured, supplied, and exported from India by established exporters, ensuring global availability and service quality.Q: What accessories are compatible with the kiln gear for installation?

A: The kiln gear is supplied with compatible accessories like couplings and bearings, which facilitate secure and efficient integration into rotary kiln drive systems.Q: How does automatic operation benefit industrial processes with kiln gear?

A: Automatic operation streamlines system control and monitoring, enhancing operational efficiency and reducing manual intervention, which leads to improved productivity in large-scale industrial setups.Q: What are the main benefits of choosing a steel kiln gear for rotary kiln drive systems?

A: Choosing a kiln gear made of steel ensures exceptional durability, resistance to deformation, and reliable performance under high-load conditions, making it a cost-effective investment for rigorous industrial processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Gears Category

Precision Gears

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Accessories Type : Bearings, Precision Shafts, Couplings

Type : Precision Gears

Material : steel

Surface Treatment : Case Hardened, Shot Peening, Phosphate Coating

Worm Wheels

Minimum Order Quantity : 1 Plant

Accessories Type : Bearings, Shafts, Bushings

Type : Worm Wheels

Material : steel

Surface Treatment : Polished

Spur Gears

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Accessories Type : Bushings, Bearings, Shafts

Type : Spur Gears

Material : steel

Surface Treatment : Polished

Helical Gears

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Accessories Type : Shafts, Bearings, Couplings

Type : Helical Gears

Material : MS, Alloy steel Carbon Steel

Surface Treatment : Polished

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese