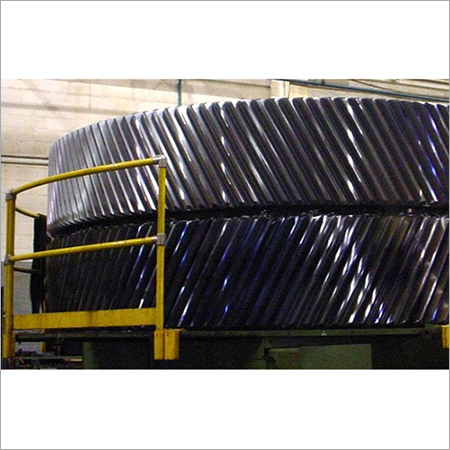

Mill Gears

Price 300000 INR/ Piece

Mill Gears Specification

- Control System

- CNC Control System

- Surface Treatment

- Polished

- Accessories Type

- Shafts, Couplings, Bearings, Gearboxes

- Features

- High Load Capacity, Shock Resistant, Long Service Life

- Machine Type

- Gearboxes, Rotary Mills, Industrial Drives

- Automation Grade

- Automatic

- Type

- Mill Gears

- Material

- steel

- Product Type

- Mill Gears

- Application

- Mill Girth Gears expertly designed for industrial applications like steel re-rolling mills, paper industries, and sugar mills.

Mill Gears Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 4 Pieces Per Month

- Delivery Time

- 15 Days

About Mill Gears

Leveraging on well equipped infrastructure facilities and dedicated staff members, we are proficient to manufacture and export an exclusive range of Mill Girth Gears. These gears are designed by our experts by utilizing the premium quality steel, iron and bronze in accordance with international quality standards. Find huge application in steel re-rolling mills, paper industries and sugar mills, these productsare used for reducing motor speed to working speed of mill.

Features of Mill Girth Gears

- Easy installation

- Low operational costs

-

Available in different hardness range

Keeping girth gears remaining working life in mind, the condition of the gear can be effectively evaluated at site. According to the findings of audit recommendations existing life of the gear or the requirement of new gear are made.

After the facing work the task of turning is carried out on special vertical turret lathes (DORRIES, FRORIEP and BERTHIEZ). Appropriate machining allowance is also needed here similar to the joint facing. And the finish machining is performed after the heat-treatment and finish-joint-facing.

Various Types of Heat Treatments:

- Volume Hardening

- Induction Hardening

- Nitriding

- Stress Relieving

-

Case Carburizing

Ashoka provides after sales technical support for all gears and pinions to its clients. And it offer on-site services on chargeable basis.

Designed for Heavy Duty Performance

Mill Gears are built from premium steel to withstand extreme mechanical loads and shocks. Their high load capacity and long service life make them suitable for industrial gearboxes, rotary mills, and large drive systems, minimizing downtime and enhancing operational stability.

Precision Manufacturing & Automation

Using a CNC control system, our automatic production process guarantees precise tooth alignment and polished finishes. This ensures compatibility with various industrial accessories such as shafts, bearings, couplings, and gearboxes, offering seamless integration into your existing machinery.

Reliability for Indian Industries

As a trusted exporter, manufacturer, and supplier in India, we supply Mill Gears to industries nationwide. Our commitment to quality and innovation delivers gears that excel in both performance and maintenance, empowering industrial operations.

FAQs of Mill Gears:

Q: How are steel Mill Gears manufactured for industrial applications?

A: Steel Mill Gears are produced using advanced CNC control systems, which automate the cutting and finishing processes. This ensures high precision, consistent quality, and polished surfaces for optimal efficiency and durability in rotary mills, industrial drives, and gearboxes.Q: What accessories are compatible with these Mill Gears?

A: Our Mill Gears are designed to integrate seamlessly with industrial accessories including shafts, couplings, bearings, and gearboxes. This allows for flexible installation and smooth operation within various machinery types.Q: When should Mill Gears be used in industrial machinery?

A: Mill Gears are ideal for situations that demand high load capacity, resistance to shock, and extended operational life, such as in rotary mills and heavy-duty gearboxes. They are particularly well-suited for continuous and rigorous industrial processes.Q: Where are these Mill Gears exported and supplied within India?

A: We export and supply Mill Gears throughout India, catering to industries in sectors like manufacturing, mining, and processing, wherever robust gear solutions are required for heavy machinery and automated systems.Q: What is the process behind the surface treatment of Mill Gears?

A: The gears undergo precision polishing as part of their surface treatment. This enhances their resistance to wear and corrosion, improves overall gear life, and reduces friction during industrial operations, contributing to smoother machinery performance.Q: How does CNC automation benefit the quality of Mill Gears?

A: CNC automation guarantees the highest levels of manufacturing accuracy. It ensures precise tooth cutting, consistent geometry, and adherence to strict technical parameters, resulting in gears with reliable performance and extended service life.Q: What are the main benefits of using these Mill Gears in industrial automation?

A: By employing steel Mill Gears with high load handling, shock resistance, and long service duration, industries experience reduced maintenance needs, higher operational efficiency, and improved safety within automated systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Gears Category

Worm Wheels

Minimum Order Quantity : 1 Plant

Color : Black

Application : used in automobile, heavy duty and aerospace application

Accessories Type : Bearings, Shafts, Bushings

Material : steel

Precision Gears

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Silver

Application : Railway Industry

Accessories Type : Bearings, Precision Shafts, Couplings

Material : steel

Herringbone Gear

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Black

Application : Heavy duty industries

Accessories Type : Couplings, Shafts, Bearing

Material : Metals/Plastics

Spur Gears

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Sliver

Application : Gear boxes machines, mining equipments, material handling equipments and gear pump units

Accessories Type : Bushings, Bearings, Shafts

Material : steel

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese