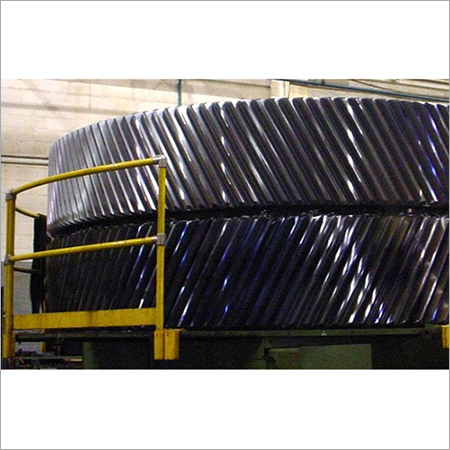

Pinion Gear

Price 25000 INR/ Piece

Pinion Gear Specification

- Accessories Type

- Shaft, Bearings, Coupling

- Machine Type

- Gearboxes, Rack-and-Pinion Systems, Mechanical Drives

- Surface Treatment

- Polished Finish

- Automation Grade

- CNC-Precision Machined

- Features

- High Strength and Durability,Compact Design,

- Type

- Pinion Gear

- Material

- steel

- Size

- 100 mm to 600 mm

- Color

- Silver

- Application

- Gearboxes, Automotive Differentials, Machine Tools, Conveyor Systems

Pinion Gear Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 4 Pieces Per Month

- Delivery Time

- 15 Days

About Pinion Gear

- Durable and robust make

- Made from carbon steel, alloy steel, cast iron and harden steel

- Teeth are available in both straight and spiral shape

- In these gears, both direction facility, i.e. Right hand and left hand are available

- The centre of gear is centre bore type

- Material used to manufacture these gears are cast iron, carbon steel, alloy steel, harden steel, bronze

- Paper Mills

- Cement Mills

- Sugar Mills

- Metal Processing Industry

- Diameter: 100 mm to 600 mm

- Number of modules: 20 modules to 50 modules

- Module availability: 20 to 50 modules per gear

- Length of outer diameter: 100 mm to 600 mm

High-Precision, Durable Pinion Gears

Experience superior reliability with our steel pinion gears, precisely machined for optimal strength and performance. Their compact construction and polished surface treatment minimize friction while supporting heavy-duty operations in diverse machinery.

Versatile Applications Across Industries

Ideal for gearboxes, rack-and-pinion systems, automotive differentials, machine tools, and conveyor systems, our pinion gears deliver consistent results. With integrated accessories, they seamlessly fit into various industrial setups, ensuring smooth operation.

FAQs of Pinion Gear:

Q: How are CNC-precision pinion gears manufactured for industrial applications?

A: Our pinion gears are produced using advanced CNC machining processes. This ensures precise dimensions and tight tolerances, resulting in high-strength steel gears with a polished finish suitable for demanding industrial machinery.Q: What benefits does a compact design offer in pinion gears used in gearboxes or conveyor systems?

A: A compact design optimizes space within gearboxes and conveyor systems. This not only increases installation flexibility but also enhances mechanical efficiency and reduces overall equipment footprint without compromising strength.Q: Where can these steel pinion gears be used most effectively?

A: These precision-machined pinion gears are highly effective in gearboxes, automotive differentials, machine tools, rack-and-pinion systems, and conveyor mechanisms, serving core roles in the mechanical drive train.Q: When should high-strength, polished pinion gears be chosen over standard gears?

A: High-strength, polished pinion gears are recommended for scenarios demanding maximum durability, precise movement, and reduced wearparticularly in high-load or critical automation settings where reliability is paramount.Q: What accessories are available with pinion gears for seamless integration?

A: Our pinion gears are available with essential accessories such as shafts, bearings, and couplings. These components aid in smooth assembly and enhance the operational stability of complete mechanical systems.Q: How can exporters, manufacturers, and suppliers in India support specialized gear requirements?

A: Exporters, manufacturers, and suppliers in India can provide custom pinion gear solutions, ensuring specific material treatments, precision levels, and compatible accessories for various industry requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Gears Category

Precision Gears

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Silver

Type : Precision Gears

Accessories Type : Bearings, Precision Shafts, Couplings

Material : steel

Worm Wheels

Minimum Order Quantity : 1 Plant

Color : Black

Type : Worm Wheels

Accessories Type : Bearings, Shafts, Bushings

Material : steel

Herringbone Gear

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Black

Type : Herringbone Gear

Accessories Type : Couplings, Shafts, Bearing

Material : Metals/Plastics

Internal Gears

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Natural Metal / Black Oxide

Type : Internal Gears

Accessories Type : Shafts, Bushings, Bearings

Material : steel

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese