ಸಿಲà³à²¸à³ ಮತà³à²¤à³ à²à³à²¯à²¾à²à²à³ ಫà³à²¯à²¾à²¬à³à²°à²¿à²à³à²¶à²¨à³

MOQ : 1 Plant

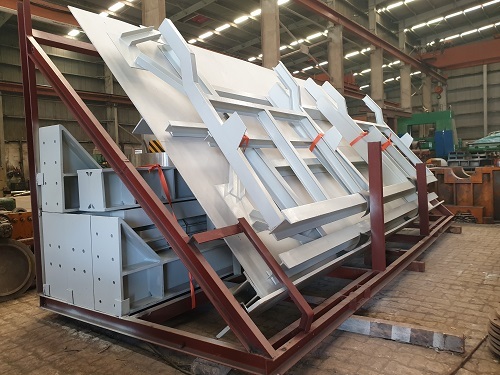

ಸಿಲà³à²¸à³ ಮತà³à²¤à³ à²à³à²¯à²¾à²à²à³ ಫà³à²¯à²¾à²¬à³à²°à²¿à²à³à²¶à²¨à³ Specification

- ಮೇಲ್ಮೈ ಮುಕ್ತಾಯ

- Sand Blasting, Polishing, Painting, Epoxy Coating

- ಗಾತ್ರ

- As per requirement

- ವಸ್ತು

- Carbon Steel, Stainless Steel, Mild Steel, Alloy Steel

- ರಕ್ಷಣೆ ಮಟ್ಟ

- Corrosion Resistant, Weather Resistant, Pressure Resistant

- ಬಳಕೆ/ಅಪ್ಲಿಕೇಶನ್ಗಳು

- Food Processing, Chemical Industry, Water Treatment

- ಫ್ಯಾಬ್ರಿಕೇಷನ್ ಸೇವೆ ವಿಧ

- Heavy Fabrication Work

- ಫ್ಯಾಬ್ರಿಕೇಷನ್ ಉತ್ಪನ್ನ

- Silos and Tank Fabrication

- ಫ್ಯಾಬ್ರಿಕೇಶನ್ ಪ್ರಕ್ರಿಯೆ

- Cutting, Rolling, Welding, Assembly, Surface Treatment

ಸಿಲà³à²¸à³ ಮತà³à²¤à³ à²à³à²¯à²¾à²à²à³ ಫà³à²¯à²¾à²¬à³à²°à²¿à²à³à²¶à²¨à³ Trade Information

- Minimum Order Quantity

- 1 Plant

- ಪೂರೈಕೆ ಸಾಮರ್ಥ್ಯ

- ತಿಂಗಳಿಗೆ

- ವಿತರಣಾ ಸಮಯ

- ತಿಂಗಳುಗಳು

About ಸಿಲà³à²¸à³ ಮತà³à²¤à³ à²à³à²¯à²¾à²à²à³ ಫà³à²¯à²¾à²¬à³à²°à²¿à²à³à²¶à²¨à³

As the name suggests, Storage Silos & Tanks are the storage equipments, which are used for the storage of dry items such as food grains, cement, and liquids such as chemicals, water etc. etc. Used for the long term or short term these are also known for their blending (mixing) of multiple items in which case these are named as Blending Silos. These can have a vast ambit of size opening from a few feet in diameter up to say 50 feet diameter and 100 feet or more of height. These are commonly designed and fabricated out of mild steels in surroundings as per customer demands in terms of capacity and type of material. Every single silo is specifically engineered to stand firm in environmental changes, seismic forces, wind loads etc. Welded silos of the Storage Silos range can be made-up by utilizing leg, skirt or structural assistance.

Different international codes are followed for designing and manufacturing of silos not only from the safety point of view but also for material strength. These specifications are utilized in conjunction with the following codifications:

- AISC - American Institute of Steel Construction

- UBC -Uniform Building Code

- AWS - American Welding Society

- FDA - Food and Drug Administration

- ASTM - American Society for Testing and Materials

- SAE - Society of Automotive Engineers

- OSHA - Occupational Safety and Health Administration

- SSPC - Steel Structures Painting Council

Design Criteria

While the designing process of silos, some primary design criteria are considered like:

- Wind factor with consolidated height, vulnerability and gust factor coefficient is also considered.

- Seismic zone/powers factor.

- Cooperative live, dead, and roof loads are consistently dealt out, with all manholes, nozzles and filter positions that are accordingly designed.

- Silo designs are based on buckling posture of the body as well as on supporting construction.

- Silos are planned to bear atmospheric pressures.

- The discharge gates/equipments, inlets are configured on the basis of load and liquidity of the material(s).

- There are assorted other design criteria such as kind of blending equipment (open air slides etc.), type of material, soil bearing capability on full load etc.

Manufacturing Specifications

Welding

- When particularized, all structural welding shall adapt to WPS regulations.

- Shell seams shall have correct incursion using grade-appropriate welding wire with automated MIG or SAW welding instrumentality.

Surface Preparation

-

All weld surfaces with distinct and sharp boundaries are ground, the undercuts are fixed, mended and re-ground. All weld spatter is abstracted and outside surfaces are grit or sand blasted as per the demand.

Coatings Carbon Steel

-

Silo exterior is glazed with minimal two rust preventive coatings that are gray or red primer (of branded manufacturer) and finishing epoxy or enamel paint in accordance with the customers requirement.

Materials Standards

Different grades of steels as per national as well as international standards are utilized for silo fabrication. All sections and plates are of proven quality from well acknowledged suppliers including European suppliers. Few of the common grades of steels utilized are-

- Steel plates as per IS 2062 Grade A/B/C, SA 516, A36, ASTM 569 etc.

- Functional shaped/sections as per ASTM A36

- Functional pipes as per ASTM A53.

- Ladders, cages, handrails, and platforms are planned to meet OSHA duties and are welded units to decrease field erection.

Rolling Capacity

Up to 100 mm Th x 3500mm L on 3 roller rolling device.

Welding Technique

Swamped metal Arc, MIG, TIG 2 mm to 8 mm electrodes.

Welder Qualification

WPS Qualified (authenticated and authorized by third party inspection agency)

Weld tests

- Radiography

- Ultrasonic experiment

- Bend testing

- 100% on weld conjuncts

Lifting Capacity

- Elevated hook cranes up to 75 MT lifting capacity

- 2 Bays with 75 MT, 1 bay with 25 MT

Impulsive Balancing

Up to 2500 mm diameter

Sand Blasting

Chamber size of 7000 mm x 7000 mm

Inflection Relieving

Furnace size of 4000 mm x 8000 mm

Steel Grade Used :

Some of the common grades of steels used by us are -

- IS 2062 Grade A/B/C

- IS 2002 Grade I/II/III Boiler Quality

- ASME SA 516 Grade 60/65/70

- ASTM A 516 Grade 60/65/70

Technical Specifications:

|

Rolling Capacity |

Up to 100 mm Th x 3500mm L on 3 roller rolling machine |

|

Welding Technique |

Welding Technique Submerged metal Arc, MIG, TIG, 2 mm to 8 mm electrodes |

|

Welder Qualification |

WPS Qualified (attested and approved by third party inspection agency) |

|

Weld tests |

Radiography, Ultrasonic testing, Bend testing, 100% on weld joints |

|

Lifting Capacity |

Overhead hook cranes up to 75 MT lifting capacity, 2 Bays with 75 MT, 1 bay with 25 MT |

|

Dynamic Balancing |

Up to 2500 mm diameter |

|

Sand Blasting |

Chamber size of 7000 mm x 7000 mm |

|

Stress Relieving |

Furnace size of 4000 mm x 8000 mm |

Advanced Surface Finishes for Extended Longevity

Our silos and tanks feature superior surface treatments such as sandblasting, polishing, painting, and epoxy coating. These finishes significantly enhance protection against corrosion, weather, and pressure, ensuring the tank remains robust and operational over prolonged usage in demanding environments.

Custom Engineering for Varied Industrial Needs

From food processing to chemical and water treatment industries, our tanks are tailored to meet specific operational requirements. We offer versatile options in materials and fabrication processes, aligning with the unique standards and conditions of each application for optimal safety and efficiency.

FAQs of Silos and Tank Fabrication:

Q: How are silos and tanks fabricated to ensure durability and resistance?

A: Our silos and tanks are fabricated using advanced methods including cutting, rolling, welding, assembly, and rigorous surface treatments like sandblasting, polishing, painting, and epoxy coating. These steps collectively provide exceptional resistance to corrosion, weather, and internal pressure.Q: What materials are used in the fabrication of these silos and tanks?

A: We utilize high-grade materials such as carbon steel, stainless steel, mild steel, and alloy steel. The choice of material depends on the intended application, environmental conditions, and client requirements.Q: When is it recommended to use these fabricated silos and tanks in your industry?

A: These tanks are suitable whenever robust, safe, and reliable storage solutions are needed, especially in industries such as food processing, chemical production, and water treatment where material integrity and resistance to corrosion and pressure are crucial.Q: Where can these silos and tanks be installed or deployed?

A: Our fabricated tanks can be installed in food processing plants, chemical manufacturing units, water treatment facilities, and other industrial settings where bulk storage of liquids or solids is required.Q: What is the process involved in manufacturing silos and tanks?

A: Manufacturing begins with material selection, followed by precision cutting, rolling, welding, assembly, and surface finishing processes. Each step is meticulously managed to ensure quality, performance, and compliance with safety standards.Q: How do the different surface finishes benefit the final product?

A: Surface treatments like sandblasting, polishing, painting, and epoxy coating protect the tanks against corrosion, improve appearance, and enhance resistance to harsh weather and extreme pressure conditions.Q: What are the main benefits of choosing your silos and tank fabrication services?

A: Clients benefit from reliable, customized storage solutions, superior protection levels, flexible applications, and compliance with international standards, supported by our expertise as an exporter, manufacturer, and supplier in India.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

ಮೊಬೈಲ್ number

Email

ಇನ್ನಷ್ಟು Products in Heavy Fabrication Works Category

ಸ್ಟ್ರಕ್ಚರಲ್ ಫ್ಯಾಬ್ರಿಕೇಶನ್ ವರ್ಕ್

ಫ್ಯಾಬ್ರಿಕೇಷನ್ ಉತ್ಪನ್ನ : Structural Fabrication Work

ಬಳಕೆ/ಅಪ್ಲಿಕೇಶನ್ಗಳು : Construction, Industrial

ಫ್ಯಾಬ್ರಿಕೇಶನ್ ಪ್ರಕ್ರಿಯೆ : Steel Frames, Beams, Columns, Trusses, Platforms, Support Structures

ಫ್ಯಾಬ್ರಿಕೇಷನ್ ಸೇವೆ ವಿಧ : Heavy Fabrication Work

ಮೇಲ್ಮೈ ಮುಕ್ತಾಯ : Sand Blasting, Grinding, Polishing

ಅಳತೆಯ ಘಟಕ : Metric Ton/Metric Tons

ಹೆವಿ ಫ್ಯಾಬ್ರಿಕೇಶನ್ ವರ್ಕ್

ಫ್ಯಾಬ್ರಿಕೇಷನ್ ಉತ್ಪನ್ನ : Heavy Fabrication Work

ಬಳಕೆ/ಅಪ್ಲಿಕೇಶನ್ಗಳು : Construction, Industrial

ಫ್ಯಾಬ್ರಿಕೇಶನ್ ಪ್ರಕ್ರಿಯೆ : Cutting, Welding, Machining, Bending,

ಫ್ಯಾಬ್ರಿಕೇಷನ್ ಸೇವೆ ವಿಧ : Heavy Fabrication Work

ಮೇಲ್ಮೈ ಮುಕ್ತಾಯ : Painted or Powder Coated

ಅಳತೆಯ ಘಟಕ : ತುಂಡು/ತುಣುಕುಗಳು

ಕಸ್ಟಮ್ ಮೇಡ್ ಸಲಕರಣೆ ಫ್ಯಾಬ್ರಿಕೇಶನ್

ಫ್ಯಾಬ್ರಿಕೇಷನ್ ಉತ್ಪನ್ನ : Custom Made Equipment Fabrication

ಬಳಕೆ/ಅಪ್ಲಿಕೇಶನ್ಗಳು : Construction, Industrial

ಫ್ಯಾಬ್ರಿಕೇಶನ್ ಪ್ರಕ್ರಿಯೆ : Cutting, Welding, Machining, Bending,

ಫ್ಯಾಬ್ರಿಕೇಷನ್ ಸೇವೆ ವಿಧ : Heavy Fabrication Work

ಮೇಲ್ಮೈ ಮುಕ್ತಾಯ : Polished, Brushed, Sandblasted

ಅಳತೆಯ ಘಟಕ : ಸಸ್ಯ/ಸಸ್ಯಗಳು

ವಿಚಾರಣೆಯನ್ನು ಕಳುಹಿಸಿ

ವಿಚಾರಣೆಯನ್ನು ಕಳುಹಿಸಿ

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese