ನà²à²²à²¿ ಶಾಫà³à²à³à²à²³à³ ಮತà³à²¤à³ ರà³à²²à³à²¸à³

Price 1000 INR/ Number

MOQ : 1 Number

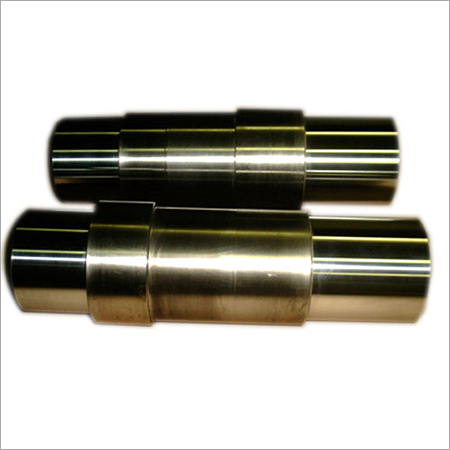

ನà²à²²à²¿ ಶಾಫà³à²à³à²à²³à³ ಮತà³à²¤à³ ರà³à²²à³à²¸à³ Specification

- ಬಳಕೆ

- diverse industrial applications like Cement, Steel, Fertilizer, Paper, Mining, and more.

- ವಸ್ತು

- ಉಕ್ಕಿನ

- ಗುಣಮಟ್ಟ ಮಟ್ಟ

- ಉತ್ಪನ್ನ ಪ್ರಕಾರ

- Forged Shafts and Rolls

- ಕೋಟಿಂಗ್

- Anti-Corrosion Coating / Heat Resistant Coating

- ಬಣ್ಣ

- Sliver

- ಗಡಸುತನ

- 50-60 HRC

- ನಿಖರತೆ

- ±0.01mm

- ದಪ್ಪ

- ಮಿಲಿಮೀಟರ್ (ಮಿಮೀ)

ನà²à²²à²¿ ಶಾಫà³à²à³à²à²³à³ ಮತà³à²¤à³ ರà³à²²à³à²¸à³ Trade Information

- Minimum Order Quantity

- 1 Number

- ಪೂರೈಕೆ ಸಾಮರ್ಥ್ಯ

- ತಿಂಗಳಿಗೆ

- ವಿತರಣಾ ಸಮಯ

- ತಿಂಗಳುಗಳು

About ನà²à²²à²¿ ಶಾಫà³à²à³à²à²³à³ ಮತà³à²¤à³ ರà³à²²à³à²¸à³

We manufacture various types of custom made Forged Shafts and Forged Rolls in forged steel construction as per EN, AISI, ASTM, IS, GS standards.

Forgings are machined on CNC lathe machines with a load carrying capacity of 10 MT single piece with varying groves, steps and keyways etc. Applications include almost all manufacturing industries such as Cement Plants, Sugar Plants, Steel Plants, Fertilizer Plants, Paper Plants, Power Plants, Rubber Industry, Mining Sector, Chemical and Mineral Ore processing plants etc.

Pinion Shafts with teeth cut portions are also manufactured.

Ashoka has exported these products to number of countries in Europe, North and South America, Africa, Middle East, Gulf, South East Asia, Australia etc.

Exceptional Material and Strength

Manufactured from premium stainless steel, our forged shafts and rolls deliver remarkable strength and resistance. Designed to endure rigorous industrial usage, the hardness range of 50-60 HRC offers excellent wear resistance, while precision engineering guarantees stable performance and long service life.

Advanced Coating for Protection

Each component is treated with either anti-corrosion or heat resistant coatings to ensure protection in extreme environments. Whether exposed to high temperatures or harsh chemicals, this specialized coating prolongs the integrity and aesthetic of the silver-finished parts, minimizing maintenance needs.

FAQs of Forged Shafts and Rolls:

Q: How are forged shafts and rolls manufactured with such high precision?

A: Our forged shafts and rolls are produced using state-of-the-art forging technology combined with rigorous quality control. Precision is ensured through advanced machining, resulting in a dimensional accuracy of 0.01mm, which is essential for high-performance industrial use.Q: What benefits does the anti-corrosion and heat resistant coating provide?

A: The specialized anti-corrosion and heat resistant coatings protect the parts from environmental damage such as rust, chemical corrosion, and temperature extremes. This ensures greater durability, reduces the need for frequent replacements, and maintains performance over time.Q: When should I consider using forged stainless steel shafts and rolls in my operations?

A: Forged stainless steel shafts and rolls are ideal for situations where superior strength, precision, and resistance to wear and corrosion are necessary. They are particularly valuable in demanding industrial applications involving high loads or exposure to harsh elements.Q: Where can these forged shafts and rolls be supplied from in India?

A: Our forged shafts and rolls are available from leading exporters, manufacturers, and suppliers across India. We ensure prompt and efficient delivery for both domestic and international clients, supporting a range of industrial sectors.Q: What is the typical process for applying anti-corrosion or heat resistant coatings?

A: The coating process involves cleaning the shaft or roll surface, followed by layer application through specialized techniques such as spraying or dipping. This ensures comprehensive coverage and strong adhesion, maximizing protective properties even in the most challenging environments.Q: How does the specified hardness of 5060 HRC benefit industrial usage?

A: A hardness of 5060 HRC means these components exhibit exceptional wear resistance and strength, making them highly reliable under heavy operational loads. This translates to enhanced longevity and reduced maintenance downtime for industries relying on robust equipment.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

ಮೊಬೈಲ್ number

Email

ವಿಚಾರಣೆಯನ್ನು ಕಳುಹಿಸಿ

ವಿಚಾರಣೆಯನ್ನು ಕಳುಹಿಸಿ

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese