ಸಿಮà³à²à²à³ ಪà³à²²à²¾à²à²à³ ಯà²à²¤à³à²°à³à²ªà²à²°à²£

Price 1000000 INR/ ತುಂಡು

MOQ : 1 ತುಂಡು

ಸಿಮà³à²à²à³ ಪà³à²²à²¾à²à²à³ ಯà²à²¤à³à²°à³à²ªà²à²°à²£ Specification

- ಉತ್ಪನ್ನ ಪ್ರಕಾರ

- Cement Plant Machinery

- ಸಾಮಾನ್ಯ ಬಳಕೆ

- Cement Plant

- ವಿಧ

- Cement Plant machinery

- ಗಣಕೀಕೃತ

- ಸ್ವಯಂಚಾಲಿತ

- ಹೌದು

- ಸ್ವಯಂಚಾಲಿತ ಗ್ರೇಡ್

- ಪಿಎಲ್ಸಿ ನಿಯಂತ್ರಣ

- ವಿಧಾನ

- ಡ್ರೈವ್ ವಿಧ

- ಎಲೆಕ್ಟ್ರಿಕ್

- ವೋಲ್ಟೇಜ್

- ವೋಲ್ಟ್ (ವಿ)

- ಮೋಟಾರ್

- ವೈಶಿಷ್ಟ್ಯ

- ಸ್ವಯಂಚಾಲಿತ ನಿಯಂತ್ರಣ ವ್ಯವಸ್ಥೆ, ಪರಿಸರ ಸ್ನೇಹಿ

ಸಿಮà³à²à²à³ ಪà³à²²à²¾à²à²à³ ಯà²à²¤à³à²°à³à²ªà²à²°à²£ Trade Information

- Minimum Order Quantity

- 1 ತುಂಡು

- ಪೂರೈಕೆ ಸಾಮರ್ಥ್ಯ

- ತಿಂಗಳಿಗೆ

- ವಿತರಣಾ ಸಮಯ

- ತಿಂಗಳುಗಳು

About ಸಿಮà³à²à²à³ ಪà³à²²à²¾à²à²à³ ಯà²à²¤à³à²°à³à²ªà²à²°à²£

We are exporter and manufacturer of Industrial Cement Plants mainly in countries Philippines, United States, Tanzania, Australia, Egypt, Argentina, Bolivia, Thailand, Ethiopia, Indonesia, Libya, Kenya, United Kingdom, Zambia etc. Contact or email for best Industrial Cement Plants at best rate .

Cement Plant Machinery :

Leveraging on our modern research & development facility, we have been able to manufacture and export Cement Plant. To design these plants in accordance with industrial standards, we source certified quality materials and components from leading vendors of the market. Immensely used for the production of high quality cements, these offered Cement Plants are easy to install and are available in different specifications given by our clients.

Features of Cement Plant Machinery :

- Best reliability and functioning

- Maximum output

- Low maintenance cost

Ashoka - As a Project Undertaker

We, Ashoka Machine Tools Corp had manufactured our first gear in the cement industry around 30 years back. Our strong clientele is the reason for our boost in this industry which keeps us enhanced by their appreciations and satisfaction. Since our inception, we have managed to manufacture diversified components and equipments for the cement industry. The range of our products comprise of machine tools, gear reducers, blowers, ball mills, crushers, rolling mills, conveyors, elevators, feeders, etc. designed according to the costumers preference. Along with being a manufacturer, Ashoka also provides specialized solutions in for small to medium scale cement plants, rotary kiln cement plants and cement plants. To offer total satisfying solutions to ನಮ್ಮ ಮೌಲ್ಯಯುತ ಗ್ರಾಹಕರು, we ensure activities relating to feasibility study, equipment manufacturing & sub- contracting, design engineering, erection & commissioning, etc. We have been one of the leading manufacturers and project undertakers.

Design Engineering:

We, at Ashoka utilize experienced and well trained engineers in order to maximize their expertize. Training of abundant human resource, their knowledge and talent combines up to a level of technical competence. To match up with international standards is the prime requirement of every firm. We believe latest upgraded machines and equipments can help us achieve a clear path of advancement in compliance with international markets. Ashoka Corp uses all the latest techniques and software like AutoCAD and ProE for construction of special computerized designs, equipment drawings, layouts and general arrangements, process flow sheets, etc. We have highly qualified and expert designers who excel in their respective fields work. Our highly dedicated and motivated team is goal oriented, and they use latest equipments and software to furnish their clients in best possible manner.

Ashoka - As a Consultant:

We believe in empowering our in-house engineering strength by lodging efficient associations and tie-ups with most well known and reputed organizations in the field of project consultancy like Holtech Consulting Pvt. Ltd. These consultancies and research centers are an important part of our teams as they provide highly expertize solutions. Ashoka Machine Tools Corp believes in rendering proper positioning and layout to its equipments to maximize the efficiency in entire manufacturing process and plant. A proper research is carried before selecting any equipments so as to ensure maximum practicability of every project in accordance to price competitiveness. To evolve the most reliable and appropriate designs for our clients we firstly know their exact requirements and investment capability, and then involve our designers and sales personnel to evolve the desired.

Turnkey - Erection & Commissioning:

Our company evolves to a proper turnkey project management system that helps in converting untouched barren lands into a highly productive commissioned plant. This level of competency at Ashoka makes it win an edge over others in the same market. Our team is sufficiently skilled and experienced who responsibly put our equipments into operation and hand running plant keys to the clients.

Our Manufacturing Ranges:

| Clinker Grinding Units | 50 TPD-1000 TPD |

| Complete Cement Plants (Including Clinker Manufacturing) | 50 TPD-1000 TPD |

| Cement Plants- with Vertical Shaft Kilns | 50 TPD-300 TPD |

| Cement Plants- with Rotary Kilns | 200 TPD-1000 TPD |

| Individual equipment and components such as jaw/hammer crushers, ball mills, ball mill drives, kilns, conveyors, elevators, feeders, blowers etc. Spare parts such as gears, gear reducers, tyres, rollers, mill headers etc. | |

Our Equipment Range:

The detailed manufacturing range of our products includes the following:

- Cement Machinery

- Ball Mills

- Vertical Shaft & Rotary Shaft Kilns

- Separators

- Crushers

- Mill Headers

- Trunion Bearings

- Vibrating Screens and Feeders

- Bucket Elevators

- Screw & Belt Conveyors

- Air Slides

- Process and Storage Hoppers

- Storage silos and aeration equipment

- Packing equipment

- Equipment Spares

Project Range

|

Clinker Grinding Units |

50 TPD-1000 TPD |

|

Complete Cement Plants (Including Clinker Manufacturing) |

50 TPD-1000 TPD |

|

Cement Plants- with Vertical Shaft Kilns |

50 TPD-300 TPD |

|

Cement Plants- with Rotary Kilns |

300 TPD-1000 TPD |

Automatic Operation for Efficient Production

Equipped with a full-fledged automatic control system, our cement plant machinery streamlines the manufacturing cycle through PLC-controlled, hydraulic operations. The electric drive (AC motor) ensures consistent and energy-efficient performance. Such automation reduces manual intervention, optimizing output while improving safety standards and reducing operational errors.

Eco-Friendly Engineering and Robust Technology

Our machinery emphasizes sustainable production, integrating environment-friendly features at every stage. The hydraulic pressure method minimizes energy waste, while electric drives further reduce emissions. These eco-conscious design choices reflect our commitment to supporting green industrial practices and helping clients align with regulatory compliance.

FAQs of Cement Plant Machinery:

Q: How does the automatic control system in the cement plant machinery work?

A: The machinery utilizes a PLC-based automatic control system, which continuously monitors and adjusts operations. By programming set parameters, the system seamlessly governs processes such as material feed, hydraulic pressure application, and motor activity, significantly reducing the need for manual oversight.Q: What are the environmental benefits of using this cement plant machinery?

A: This equipment features environment-friendly engineering, such as efficient electric drive and hydraulic pressure method, which reduces energy consumption and minimizes emissions. These attributes support sustainable production and help plants achieve compliance with environmental regulations.Q: When is the optimal time to use fully automatic cement plant machinery?

A: Fully automatic cement plant machinery is best utilized in large-scale manufacturing projects where consistent quality, high output rates, and minimized labor costs are priorities. Its reliable automation is especially advantageous during continuous operations and for meeting tight project timelines.Q: Where can this machinery be installed or operated?

A: The plant machinery is designed for installation in industrial cement manufacturing facilities. As an exporter, manufacturer, and supplier in India, we provide solutions suitable for both new installations and upgrades at existing cement plants, ensuring compatibility with industry standards.Q: What is the process managed by the machinerys hydraulic pressure method?

A: The hydraulic pressure method is used to compact and shape cement mixtures efficiently. Automated controls govern the application of hydraulic force, ensuring uniform consistency and strength in the final product while maintaining high throughput rates.Q: How is the equipment powered, and what is the required voltage?

A: The cement plant machinery operates using AC motors with an electric drive, and requires a standard industrial power supply of 380 Volts. This setup ensures robust, uninterrupted operation in demanding manufacturing environments.Q: What advantages do customers gain from choosing your automated and environment-friendly cement plant machinery?

A: Customers benefit from increased productivity, reduced labor costs, consistent product quality, and improved environmental compliance. The automation and energy-efficient features simplify operation, enhance safety, and support sustainable, future-ready manufacturing processes.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

ಮೊಬೈಲ್ number

Email

ಇನ್ನಷ್ಟು Products in Cement Plant Machinery Category

ಸಿಮೆಂಟ್ ಪ್ಲಾಂಟ್ ಪ್ರಾಜೆಕ್ಟ್

ಬೆಲೆ ಅಥವಾ ಬೆಲೆ ಶ್ರೇಣಿ : INR

ವಿಧಾನ : Hydraulic Pressure

ವಿಧ : Cement Plant

ವೋಲ್ಟೇಜ್ : ವೋಲ್ಟ್ (ವಿ)

ಪಿಎಲ್ಸಿ ನಿಯಂತ್ರಣ : Yes

ಗಣಕೀಕೃತ : No

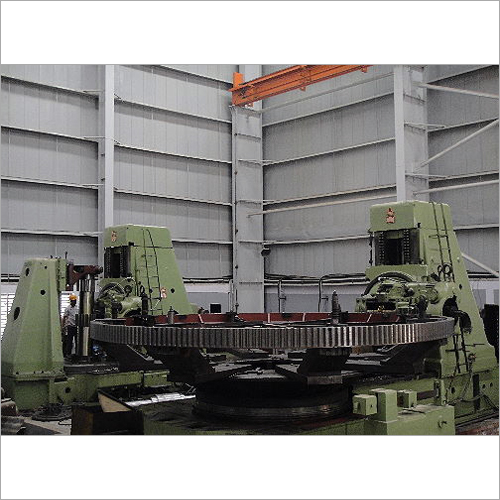

ಸಿಮೆಂಟ್ ಮಿಲ್ ಸುತ್ತಳತೆ ಗೇರ್

ಬೆಲೆ ಅಥವಾ ಬೆಲೆ ಶ್ರೇಣಿ : INR

ವಿಧಾನ : Hydraulic Pressure

ವಿಧ : Cement Plant machinery

ವೋಲ್ಟೇಜ್ : ವೋಲ್ಟ್ (ವಿ)

ಪಿಎಲ್ಸಿ ನಿಯಂತ್ರಣ : Yes

ಗಣಕೀಕೃತ : No

ವಿಚಾರಣೆಯನ್ನು ಕಳುಹಿಸಿ

ವಿಚಾರಣೆಯನ್ನು ಕಳುಹಿಸಿ

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese