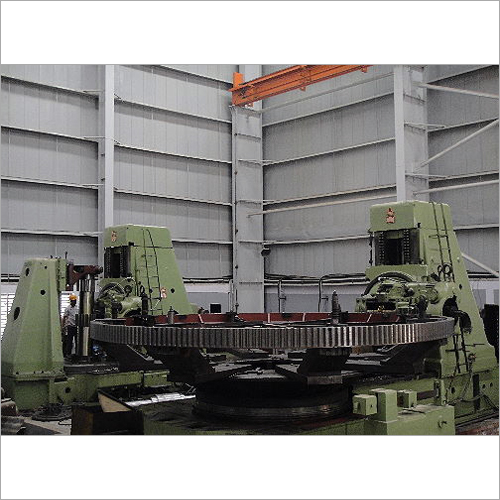

ಸಿಮà³à²à²à³ ಮಿಲೠಸà³à²¤à³à²¤à²³à²¤à³ à²à³à³à²°à³

Price 200000 INR/ Plant

ಸಿಮà³à²à²à³ ಮಿಲೠಸà³à²¤à³à²¤à²³à²¤à³ à²à³à³à²°à³ Specification

- ಉತ್ಪನ್ನ ಪ್ರಕಾರ

- Cement Mill Girth Gear

- ಸಾಮಾನ್ಯ ಬಳಕೆ

- Cement Plant machinery

- ವಿಧ

- Cement Plant machinery

- ಗಣಕೀಕೃತ

- ಸ್ವಯಂಚಾಲಿತ

- ಸ್ವಯಂಚಾಲಿತ ಗ್ರೇಡ್

- ಸೆಮಿ ಸ್ವಯಂಚಾಲಿತ

- ಪಿಎಲ್ಸಿ ನಿಯಂತ್ರಣ

- ವಿಧಾನ

- ಡ್ರೈವ್ ವಿಧ

- ಎಲೆಕ್ಟ್ರಿಕ್

- ವೋಲ್ಟೇಜ್

- ವೋಲ್ಟ್ (ವಿ)

- ವೈಶಿಷ್ಟ್ಯ

- ,

- ಖಾತರಿ

- 1 Year

ಸಿಮà³à²à²à³ ಮಿಲೠಸà³à²¤à³à²¤à²³à²¤à³ à²à³à³à²°à³ Trade Information

- Minimum Order Quantity

- 1 Plant

- ಪೂರೈಕೆ ಸಾಮರ್ಥ್ಯ

- ತಿಂಗಳಿಗೆ

- ವಿತರಣಾ ಸಮಯ

- ತಿಂಗಳುಗಳು

About ಸಿಮà³à²à²à³ ಮಿಲೠಸà³à²¤à³à²¤à²³à²¤à³ à²à³à³à²°à³

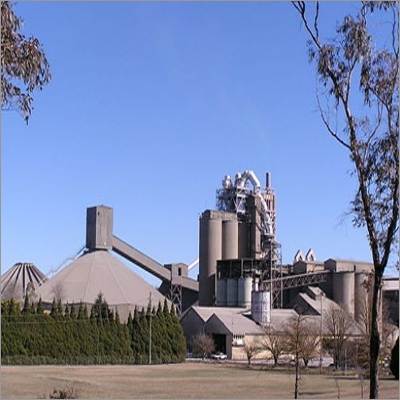

We are exporter and manufacturer of Cement Plant Ring Gear mainly in countries Philippines, United States, Tanzania, Australia, Egypt, Argentina, Bolivia, Thailand, Ethiopia, Indonesia, Libya,Kenya, United Kingdom, Zambia etc. We are exporting Cement Plant Ring Gear to fulfill our buyers requirement on regular basis.

Stagewise tests are also conducted at different manufacturing stages. Third party tests agencies also test like TPL, MOODY, LLOYDS, SGS, DNV, etc. these Cement Plant Ring Gear to ensure subsequent qualitative clearance.

Finite Element Analysis:

We are one of the prime Cement Plant Ring Gear Manufacturers In India. We also provide load and stress analysis on the gears utilizing finite element analysis to test suitable selection of the geometrical designs and materials.

Reverse Engineering and Designing

If transporting the gears to our modern manufacturing facility is possible, then reverse engineering and designing is conducted to design the drawings accurately as per sample. In addition to this, job is also loaded on to the appropriate machine to attain precise geometrical sizing.

Gears Pinion Shafts Manufacturers

Cement Plant Ring Gear inspections are conducted by employing mechanical, special hand, and automatic instruments by well-known companies like MITOTOYO. From dimensional measurements to chemical testing, hardness testing and mechanical testing are also carried -out.

Non destructive testing such as magnetic particle inspections (MPI) and ultrasonic testing (UST) is done for internal flaws. Surface crack detection tests include developer penetrant testing (DP). Gear tooth profiles are tested employing special instruments like profiles testers, vernier calibers etc. Appropriate contact on the tooth flanks of girth gear is tested to ensure the best meshing between the teeth.

ASHOKA renders complete supervision of on-site installation of the Cement Plant Ring Gear by the companies in India. An expert supervision is deputed to the site, whereas local manpower, equipment like movable cranes etc. are provided by the clients. We also provide lifetime after sales technical support to clients for all girth gears. The support services are also provided irrespective of the guarantee period. On-site support is offered on chargeable basis.

Efficient and Reliable Semi-Automatic Operation

The Cement Mill Girth Gear boasts semi-automatic functionality with PLC control to streamline operations. The electric drive type ensures optimal power efficiency, while its robust design makes it suitable for continuous use in demanding environments. Using hydraulic pressure as the core method, this solution delivers consistent results in cement processing plants.

Designed for Sustainability and Quality

Constructed with high-quality materials, the girth gear prioritizes longevity while maintaining an environmentally friendly profile. Its 380V electric system balances performance and energy consumption. As a non-computerized unit, maintenance is straightforward, and the included 1-year warranty gives users peace of mind regarding product reliability.

FAQs of Cement Mill Girth Gear:

Q: How does the PLC control system improve the operation of the Cement Mill Girth Gear?

A: The PLC control system automates key functions, increases precision in gear operation, and enables easier monitoring and adjustment of settings, which leads to more efficient and reliable cement milling processes.Q: What is the method used for the Cement Mill Girth Gears operation?

A: This girth gear uses hydraulic pressure as its primary method of operation, ensuring smooth transmission of power and consistent performance, especially under high-load conditions in cement mills.Q: When is maintenance required for the Cement Mill Girth Gear and what does it involve?

A: Regular maintenance should be scheduled annually or as needed depending on usage intensity. It generally involves inspecting the gear teeth, checking lubrication, and verifying the integrity of hydraulic and electrical components.Q: Where can the Cement Mill Girth Gear be installed?

A: Designed for industrial environments, it is ideally suited for installation in cement manufacturing plants, where robust, high-quality gear mechanisms are essential for milling operations.Q: What benefits does the environment-friendly design offer to users?

A: The environment-friendly construction helps reduce energy consumption and operational emissions, contributing to sustainable manufacturing practices while also potentially lowering long-term costs.Q: How does the one-year warranty benefit buyers and users of the Cement Mill Girth Gear?

A: The included one-year warranty assures users of the products reliability and quality, offering coverage against manufacturing defects and ensuring support from the manufacturer, supplier, or exporter.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

ಇನ್ನಷ್ಟು Products in Cement Plant Machinery Category

ಸಿಮೆಂಟ್ ಪ್ಲಾಂಟ್ ಪ್ರಾಜೆಕ್ಟ್

ಅಳತೆಯ ಘಟಕ : Plant/Plants

ಸ್ವಯಂಚಾಲಿತ ಗ್ರೇಡ್ : ಸಂಪೂರ್ಣ ಸ್ವಯಂಚಾಲಿತ

ವೈಶಿಷ್ಟ್ಯ : ಉನ್ನತ ಗುಣಮಟ್ಟ

ವಿಧಾನ : Hydraulic Pressure

ಪಿಎಲ್ಸಿ ನಿಯಂತ್ರಣ : Yes

ಗಣಕೀಕೃತ : No

ಸಿಮೆಂಟ್ ಪ್ಲಾಂಟ್ ಯಂತ್ರೋಪಕರಣ

ಅಳತೆಯ ಘಟಕ : ತುಂಡು/ತುಂಡುs

ಸ್ವಯಂಚಾಲಿತ ಗ್ರೇಡ್ : Fully Automatic

ವೈಶಿಷ್ಟ್ಯ : ಸ್ವಯಂಚಾಲಿತ ನಿಯಂತ್ರಣ ವ್ಯವಸ್ಥೆ, ಪರಿಸರ ಸ್ನೇಹಿ

ವಿಧಾನ : Hydraulic Pressure

ಪಿಎಲ್ಸಿ ನಿಯಂತ್ರಣ : Yes

ಗಣಕೀಕೃತ : No

ವಿಚಾರಣೆಯನ್ನು ಕಳುಹಿಸಿ

ವಿಚಾರಣೆಯನ್ನು ಕಳುಹಿಸಿ

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese