Kiln Tyre

Price 100000 INR/ Plant

Kiln Tyre Specification

- Diameter

- 2-7 Meter (m)

- Drive Type

- Three Phase AC 440 V

- Noise Level

- Less than 80 db

- Features

- Heavy Duty

- Surface Finish

- Polished

- Shape

- Round

- Size

- 2meter to 7meter

- Usage & Applications

- usage in cement, metal casting, mining and dyeing industries.

- Product Type

- Machine Accessories

- Material

- Steel

- Technology

- CNC

- Power Source

- Electricity

- Voltage

- 440 Volt (v)

- Surface Treatment

- Coated

- Warranty

- 1 Year

Kiln Tyre Trade Information

- Minimum Order Quantity

- 1 Plant

- Supply Ability

- 100 Plants Per Month

- Delivery Time

- 1 Months

About Kiln Tyre

- Enhance the temperature of materials

- High-quality raw materials used

- Maximum durability

- Precise design

- Developed as per the IS 2062 standards

- Mounting features are simple bore, hubless, keyway and D teeth cutting

- Outer diameter is from 2mtr to 7mtr

- Thickness of shell is 2mtr to 7mtr

- Cement

- Metal Casting

- Dyeing

- Mining

Advanced Engineering for Industrial Reliability

Designed for rigorous industrial environments, our Kiln Tyre leverages precision CNC technology and galvanization to guarantee robust performance. The copper-polished steel construction not only delivers mechanical strength but also resists wear and corrosion. Our commitment to quality workmanship ensures reliable operation, making this product a preferred choice among manufacturers worldwide.

Unmatched Durability and Longevity

With galvanizing surface treatment and a polished copper finish, the Kiln Tyre endures challenging conditions while maintaining its structural integrity. Our one-year warranty reflects confidence in its longevity. From cement plants to chemical industries, customers benefit from reduced downtime and sustained productivity when choosing our engineered solution.

FAQs of Kiln Tyre:

Q: How is the Kiln Tyre manufactured to ensure high precision and quality?

A: The Kiln Tyre is manufactured using CNC (Computer Numerical Control) technology, which ensures consistency, high precision, and uniformity across all units. The steel is skillfully machined and then polished to a copper finish, followed by a galvanizing process for added durability.Q: What industrial applications is this Kiln Tyre best suited for?

A: This Kiln Tyre is designed primarily for heavy-duty industrial applications, such as rotary kilns in the cement, chemical, and metallurgical sectors, where robust support and sustained performance are required.Q: When should I consider replacing my existing kiln tyre with this model?

A: Consider replacing your existing kiln tyre when there are visible signs of excessive wear, corrosion, or difficulty maintaining operational efficiency. Our kiln tyres superior steel construction and surface treatments make it an excellent upgrade for aging or underperforming equipment.Q: Where is this Kiln Tyre produced and can it be exported internationally?

A: The Kiln Tyre is manufactured in India by a recognized exporter, manufacturer, and supplier. We offer international shipping and have established supply chains to serve clients worldwide.Q: What is the process involved in installing the Kiln Tyre?

A: Installation involves careful mounting onto the kiln shell, aligning it under proper guidance, and securing it firmly as part of regular kiln maintenance. Due to its CNC machining and precision engineering, the tyre fits seamlessly, minimizing installation time.Q: How does the galvanizing surface treatment benefit the Kiln Tyre?

A: Galvanizing enhances the tyres resistance to corrosion, increasing its service life even under harsh operational conditions. It also reduces maintenance requirements, making it ideal for long-term, demanding use.Q: What are the main benefits of choosing this Kiln Tyre for my operation?

A: Selecting this kiln tyre means benefiting from advanced engineering, improved durability, lower maintenance, and guaranteed quality backed by a one-year warranty. It supports enhanced efficiency and operational reliability for your industrial processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mill & Kiln Spares Category

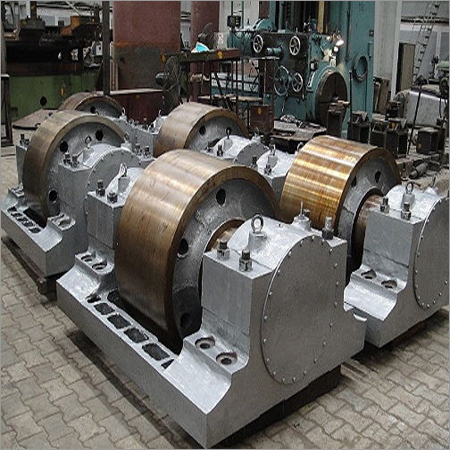

Kiln Support Roller

Price 100000 INR / Plant

Minimum Order Quantity : 1 Plant

Color : Sliver

Usage & Applications : used in various mills for proper and hassle free functioning

Product Type : Machine Accessories

Material : Cast and forged alloy steels

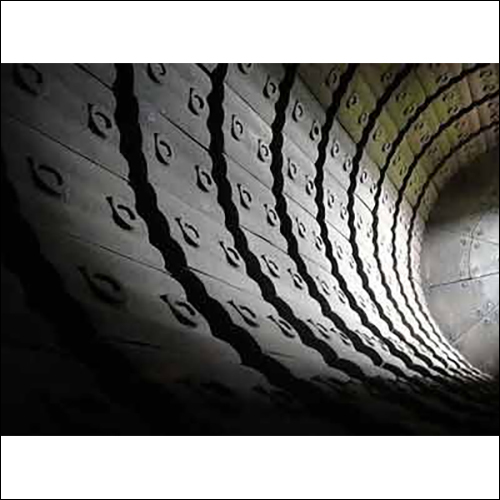

Ball Mill Liners

Price 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Color : Gray

Usage & Applications : Cement,Mining, Metal casting, Dyeing

Product Type : Machine Parts

Material : Stainless Steel

Ball Mill Headers

Price 200000 INR / Plant

Minimum Order Quantity : 1 Plant

Color : Sliver

Usage & Applications : Ball Mills, Rod Mills

Product Type : Machine Accessories

Material : Steel

Kiln Shells

Price 200000 INR / Plant

Minimum Order Quantity : 1 Plant

Color : Brown

Usage & Applications : used during the production process of metals, construction materials, sponge iron, chemicals, cement, refractories, petroleum and gypsum

Product Type : Machine Parts

Material : Stainless Steel

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese