Kiln Shells

Price 200000 INR/ Plant

Kiln Shells Specification

- Shape

- cylindrical shape

- Drive Type

- Electric

- Usage & Applications

- used during the production process of metals, construction materials, sponge iron, chemicals, cement, refractories, petroleum and gypsum

- Features

- High Strength, Wear Resistant, Precision Tooth Profile

- Surface Finish

- Polished

- Product Type

- Machine Parts

- Material

- Stainless Steel

- Technology

- CNC

- Voltage

- 380-440 Volt (v)

- Surface Treatment

- Painted

- Color

- Brown

- Warranty

- 1 Year

Kiln Shells Trade Information

- Minimum Order Quantity

- 1 Plant

- Supply Ability

- 100 Plants Per Month

- Delivery Time

- 1 Months

About Kiln Shells

Came into existence in the year 1968, we are famous as one of the fastest growing manufacturers and exporters of best quality Kiln Shells. It is a rotating inclined cylinder shape furnace, fired from one end to generate heat. Widely used during the production process of metals, construction materials, sponge iron, chemicals, cement, refractories, petroleum and gypsum, these products used various types of fuels for heating purpose.

Features:

- High functionality

- Accurate dimensions

- Optimum performance

Application:

A rotary Kiln shell is a type of inclined cylindrical shaped rotating furnace which is used to heat solids to a temperature level when a chemical reaction is triggered through a wet or dry process. These kilns have a huge demand in the production of petroleum coke, refractories, sponge iron, alumina, gypsum, construction materials, chemicals, cement, metals, etc.

Working Principal:

The working principal of rotary kiln involves the firing of an inclined cylinder to generate heat from one end to all over its path. These Kilns generally fired directly and covered with refractory material to safeguard the steel shell to minimize loss by radiation and convey heat to the material.

All types of kilns are excellent heat exchangers that transfer heat through various modes like conduction, radiation and convection.

Different types of fuels which are used to ignite the kiln are petroleum coke, ground coal, gasses, fuel oils, and many more. Selection of fuel mostly depends upon the economics behind the consumption of a particular fuel. Transferring heat through gas radiation is an effective way to convey comparatively smaller amount of heat. Conduction to the charge and radiation from hot flame are reliable for hot bricks transfer.

Inclination of the kiln makes the processed material to move towards discharge point with every rotation taken by the entire body. From entry to discharge the form of material completely changes.

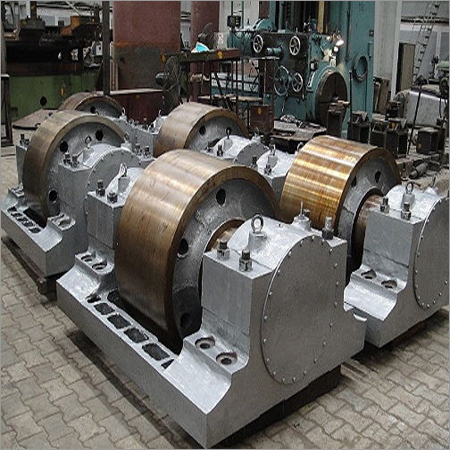

General Design Features:

A basic Rotary Kiln Shell is a shell of cylindrical shape, with inclination from the horizontal and support on two or more riding rings also known as tyre stations. These are the base on which the supporting rollers rest. One among the tyre is mounted axially with the help of a set of thrust rollers to resit the load of of thrust during the movement of kiln and hence preventing the kiln from getting shifted from its axis. A pinion arrangement and girth gear assist in the rotation of the drum assembly. Prime movers in the rotary kilns are the gear reducers which are used to reduce or increase speed and torque as per the requirements. The designing of gear reducers can be done according to the needs of varied applications. On the gear support base the girth gear is mounted away from the shell end to protect it from encountering high temperature. The thermal expansion is compensated by the mounting of girth gear on the tangential spring plates fixed to the shells. Also, the driving pinion is affixed on the shaft that produces the output in helical gears/ worm.

Each moving piece of the equipment has frictionless bearings. These bearings are exclusively designed as per the application. Anti-friction bearings, also known as roller bearings, are the most common bearing. They give outstanding performance in any working condition. But, roller bearings are not suitable applications involving heavy loads. For this purpose, different types of bearing are utilized.

The length and the shell diameter of bearings are specifically designed to suit unique products and different capacities of production. Proper selection of length, speed, diameter, slope, and the interior design plays major role in setting the solid retention time of the kiln.

Sealing Arrangement:

To prevent environmental air from entering, seal is necessary at each end of kiln. Any accidental air leakage can have different effect on the entire process. In some cases, it minimizes the efficiency and in others it can generate very unstable and unsafe conditions. The temperature and volume of the flowing gases are properly maintained by preventing the leakage of cold air inside kiln, especially on the area where the rotating shell enters the discharge and feed hoods. For this, reliable seal rings are fitted. There are different types of seal rings utilized for preventing leakage. The spring load type are the rings in which the finished metal surfaces are in contact with the support of spring. Continuous replacement and adjustments are required for sealing segments.

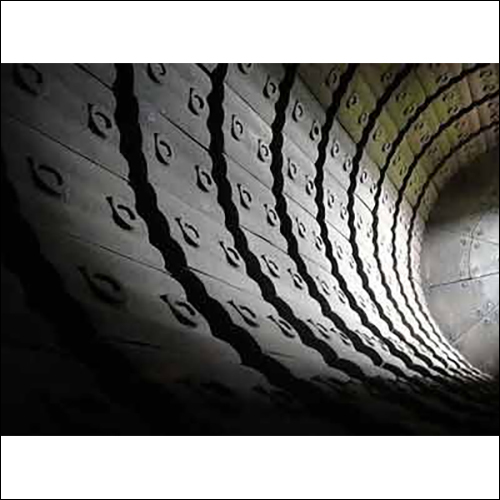

Refractory Lining

Due to the abrasive material and high temperature, wear resistant lining or refractory is required in a rotary kiln. This solid box refractory is installed in assorted areas very securely in a circumferential formation. With different compositions, the bricks have various types of properties like resistance to wear, maximum temperature bearing capacity and insulation value. Application where the use of bricks is not suitable, castable or liquid refractors are utilized with the support of anchors. Optionally, kilns have specific insulation material under the brick to get an extra layer to aid in the reduction of shell losses.

Firing System

One of the most essential and integral components of a rotary kiln is its burner system. It is used to optimize the fuel combustion for the purpose of heat release in the kiln. Some of the parameters which a kiln operator must consider in the selection of furnace are flexibility & ease of operation, safety considerations, energy efficiency, environmental impact, product quality, maintenance costs, etc.

The working principal of rotary kiln includes direct heat injection at the end of the furnace. System fitted for the firing of different types of combustion fuels could be of any size and design. Burner is fitted on the area where the fuel is lighted. Mixing of air with the fuel could be done before or inside the burner. Temperature of the fuel is dependent upon the fuel/ air ratio, fuel type and other conditions of burning.

Dust Collection Arrangement

Fumes of oil fired furnace contain definite proportion of minute dust which boards the air steam during contact with the heated materials. A high efficiency dust cyclone is utilized as a measure for pollution control. No matter how efficient these dry collectors are, they are not able to completely collect the dust. For this, wet collectors are used in the form of bag filter or sludge.

|

Specification |

2.8/2.5-44 |

348 |

3.2-50 |

3.3-50 |

3.5-54 |

4-60 |

4.3-64 |

4.8-74 |

5.0-74 |

|

Production |

300 |

600-700 |

1000 |

1200 |

1500-1800 |

2500 |

3500 |

5000 |

6000 |

|

rake of Kiln |

3.5 |

3.5 |

3.5 |

4 |

4 |

4 |

4 |

4 |

4 |

|

Number of bearings |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

3 |

|

Primary Power Rating (kw) |

55 |

100 |

160 |

160 |

220 |

315 |

400 |

630 |

710 |

|

Reduction Ratio (For Gear Reducer) |

49-63 |

50 |

40 |

40 |

28 |

22.4 |

31.5 |

42.226 |

28 |

Superior Features for Industrial Demands

Our kiln shells are constructed from high-strength stainless steel, equipped with a precision tooth profile for enhanced operational accuracy. The surface receives both polishing and paint treatment, resulting in improved resistance to wear and corrosion. Precision CNC technology ensures a flawless finish and consistent dimensional accuracy, setting our product apart in rigorous industrial environments.

Comprehensive Warranty and Support

Every kiln shell comes with a 1-year warranty, covering manufacturing defects and assuring uninterrupted functionality. As experienced exporters, manufacturers, and suppliers in India, we provide full technical support and service throughout the products lifespan, ensuring peace of mind and reliable performance for clients worldwide.

FAQs of Kiln Shells:

Q: How are kiln shells manufactured to achieve high strength and wear resistance?

A: Kiln shells are fabricated from stainless steel using advanced CNC technology, which ensures uniform strength and a precision tooth profile. The polished and painted surface treatments further enhance their resilience against industrial wear and corrosion.Q: What benefits does the precision tooth profile offer for industrial applications?

A: The precision tooth profile, achieved through CNC machining, improves engagement with other kiln components, enabling smoother operations and reducing mechanical stress. This results in increased efficiency and longevity in demanding industrial settings.Q: When should kiln shells be replaced in an industrial setup?

A: Kiln shells should be replaced when visible signs of excessive wear, distortion, or compromised structural integrity occur, or at regular maintenance intervals as recommended by operational guidelines. Annual inspections are advised to ensure optimal function.Q: Where are these kiln shells commonly used?

A: These kiln shells are utilized in various industrial sectors, including cement manufacturing, metal processing, and ceramics production. Their robust design suits environments that demand consistent strength and resistance to abrasive conditions.Q: What is the process for ordering kiln shells from Indias exporter, manufacturer, and supplier network?

A: To order, simply contact our network of exporters, manufacturers, or suppliers in India. We provide guidance on product selection, customization options, and offer shipping solutions tailored to your industrial requirements.Q: How does the surface finish and painted color contribute to product durability?

A: The polished finish reduces friction and wear, while the painted brown color acts as an additional barrier against corrosion and environmental impact, thus extending the lifespan of the kiln shell in industrial operations.Q: What usage guidelines maximize the benefits of using stainless steel kiln shells?

A: For optimum performance, ensure proper installation, adhere to manufacturer-specified maintenance schedules, and regularly inspect the shells for wear. Proper usage leverages their high strength and wear resistance, maximizing equipment efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mill & Kiln Spares Category

Kiln Tyre

Price 100000 INR / Plant

Minimum Order Quantity : 1 Plant

Features : Heavy Duty

Surface Finish : Polished

Material : Steel

Usage & Applications : usage in cement, metal casting, mining and dyeing industries.

Kiln Support Roller

Price 100000 INR / Plant

Minimum Order Quantity : 1 Plant

Features : High load capacity, long service life, precision engineered, wear resistant

Surface Finish : Smooth, Machined, AntiCorrosive

Material : Cast and forged alloy steels

Usage & Applications : used in various mills for proper and hassle free functioning

Ball Mill Liners

Price 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Features : High Strength, Wear Resistant, Precision Tooth Profile

Surface Finish : Smooth

Material : Stainless Steel

Usage & Applications : Cement,Mining, Metal casting, Dyeing

Ball Mill Headers

Price 200000 INR / Plant

Minimum Order Quantity : 1 Plant

Features : High Strength, Wear Resistant, Precision Tooth Profile

Surface Finish : Polished

Material : Steel

Usage & Applications : Ball Mills, Rod Mills

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese