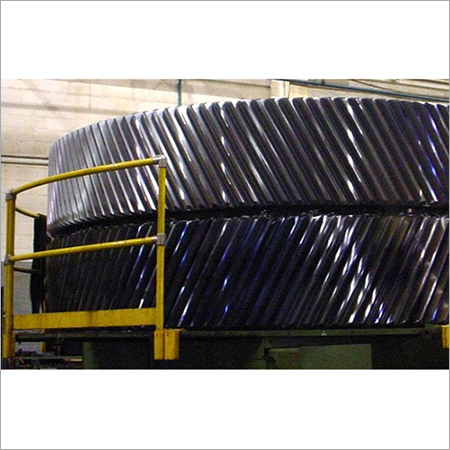

Internal Gears

Price 100000 INR/ Piece

Internal Gears Specification

- Automation Grade

- Manual

- Accessories Type

- Shafts, Bushings, Bearings

- Machine Type

- ear Shaping Machine / CNC Gear Grinder

- Features

- High Torque Transmission, Compact Design, Smooth Operation, High Load Capacity

- Type

- Internal Gears

- Size

- UP to 3000 mm internal diameter

- Material

- steel

- Product Type

- Internal Gears

- Color

- Natural Metal / Black Oxide

- Application

- Material handling equipment machine tools

Internal Gears Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 4 Pieces Per Month

- Delivery Time

- 15 Days

About Internal Gears

- Type: Spur

- Capacity: UP to 3000 mm internal diameter

- Applications: Material handling equipment machine tools

Robust Performance for Industrial Applications

Our internal gears are designed to handle rigorous industrial demands, particularly in applications involving material handling equipment and machine tools. With their high torque transmission and ability to operate smoothly under heavy loads, these gears support reliable functioning in complex manufacturing environments.

Precision Engineering and Quality Materials

We manufacture internal gears using advanced ear shaping and CNC gear grinding technologies. Constructed from premium steel, these gears offer high load capacity, durability, and longevity. Their compact design allows for easy integration into systems requiring precise motion control.

FAQs of Internal Gears:

Q: How are internal gears manufactured for industrial applications?

A: Internal gears are crafted using ear shaping machines and CNC gear grinders, ensuring precision and smooth operation. High-quality steel is used to achieve excellent load capacity and torque transmission, making them suitable for heavy-duty industrial environments.Q: What are the main benefits of using internal gears in material handling equipment?

A: Internal gears provide high torque transmission, compact design, and smooth operation, all vital for material handling equipment. These features optimize performance, enhance load handling, and ensure longevity in demanding conditions.Q: When should internal gears be selected over external gears?

A: Internal gears are preferred when compact size, enhanced torque transmission, and smooth operation are necessary. They are ideal for confined spaces and applications requiring steady, high-load movement, such as in machine tools and automated machinery.Q: Where can these internal gears be used?

A: These gears are commonly employed in machine tools and material handling equipment across industrial and manufacturing sectors. Their robust features make them suitable for environments demanding efficient power transmission and high durability.Q: What is the process for integrating internal gears with accessories like shafts and bearings?

A: Integration involves aligning and assembling internal gears with compatible shafts, bushings, and bearings. Precision mounting and proper lubrication are essential to achieve seamless operation and minimize wear, extending the life of the gear assembly.Q: How does the manual automation grade impact gear operation?

A: Internal gears supplied with a manual automation grade require manual intervention for operation and adjustment, offering flexibility in settings. This is beneficial in industrial setups where customizability and control are essential for specific applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Gears Category

Worm Wheels

Minimum Order Quantity : 1 Plant

Type : Worm Wheels

Material : steel

Accessories Type : Bearings, Shafts, Bushings

Application : used in automobile, heavy duty and aerospace application

Kiln Gear

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Kiln Gear

Material : steel

Accessories Type : Couplings, Bear'ings, Lubrication Systems

Application : Ball mills, rod mills, rotary kilns, rotary coolers, crusher mills, mining, steel plants, power plants, paper plants, fertilizer plants, grinding applications, heavy machinery etc.

Herringbone Gear

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Herringbone Gear

Material : Metals/Plastics

Accessories Type : Couplings, Shafts, Bearing

Application : Heavy duty industries

Mill Gears

Price 300000 INR / Piece

Minimum Order Quantity : 1 Piece

Type : Mill Gears

Material : steel

Accessories Type : Shafts, Couplings, Bearings, Gearboxes

Application : Mill Girth Gears expertly designed for industrial applications like steel rerolling mills, paper industries, and sugar mills.

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese