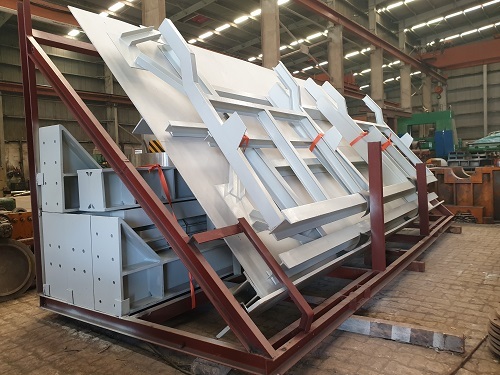

Custom Made Equipment Fabrication

Price 1000000 INR/ Plant

Custom Made Equipment Fabrication Specification

- Protection Level

- Corrosion Resistant, Heat Resistant, Wear Resistant

- Usage & Applications

- Construction, Industrial

- Size

- As per requirement

- Material

- Carbon Steel, Stainless Steel, Aluminum, Alloy Steel

- Surface Finish

- Polished, Brushed, Sandblasted

- Coating Material

- Powder Coating, Epoxy Paint, Galvanizing

- Fabrication Service Type

- Heavy Fabrication Work

- Fabrication Product

- Custom Made Equipment Fabrication

- Fabrication Process

- Cutting, Welding, Machining, Bending,

Custom Made Equipment Fabrication Trade Information

- Minimum Order Quantity

- 1 Plant

- Supply Ability

- 100 Plants Per Month

- Delivery Time

- 1 Months

About Custom Made Equipment Fabrication

We are exporter and manufacturer of Custom Made Equipment Fabrication mainly in countries Philippines, United States, Tanzania, Australia, Egypt, Argentina, Bolivia, Thailand, Ethiopia, Indonesia, Libya,Kenya, United Kingdom, Zambia etc. We are exporting Custom Made Equipment Fabrication to fulfill our buyers requirement on regular basis.

|

Rolling Capacity |

Upto 100 mm Th x 3500mm L on 3 roller rolling machine |

|

Welding Technique |

Submerged metal Arc, MIG, TIG 2 mm to 8 mm electrodes |

|

Welder Qualification |

WPS Qualified (attested and approved by third party inspection agency) |

|

Weld tests |

Radiography Ultrasonic testing Bend testing 100% on weld joints |

|

Lifting Capacity |

Overhead hook cranes upto 75 MT lifting capacity 2 Bays with 75 MT, 1 bay with 25 MT |

|

Dynamic Balancing |

Up to 2500 mm diameter |

|

Sand Blasting |

Chamber size of 7000 mm x 7000 mm |

|

Stress Relieving |

Furnace size of 4000 mm x 8000 mm |

Premium Protection for Demanding Applications

Our fabricated equipment is engineered to withstand harsh environments, offering robust corrosion, heat, and wear resistance. Each product is treated with high-quality coatings such as powder coating and epoxy paint, as well as galvanizing for added durability. These protective measures ensure long-lasting performance, making them suitable for both construction and heavy industrial use.

Versatile Material and Finish Selection

Choose from a wide selection of materials, including carbon steel, stainless steel, aluminum, and alloy steel, to match your specific requirements. Surface finishes are available in polished, brushed, and sandblasted styles, offering both aesthetic appeal and functional protection. This versatility ensures optimal results for various usage scenarios.

FAQs of Custom Made Equipment Fabrication:

Q: How is custom equipment fabricated to achieve corrosion, heat, and wear resistance?

A: Our custom fabrication process combines advanced cutting, welding, machining, and bending techniques with the use of high-performance materials. We finish each product with coatings like powder coating, epoxy paint, and galvanizing, which enhance resistance against corrosion, heat, and wear, ensuring equipment longevity in challenging environments.Q: What materials can be used for custom equipment fabrication?

A: We offer fabrication services using a variety of quality materials, including carbon steel, stainless steel, aluminum, and alloy steel. The choice of material depends on your specific application requirements and desired protection levels.Q: When should I choose custom made equipment for my construction or industrial project?

A: Opt for custom made equipment fabrication whenever you require specialized dimensions, enhanced durability, or unique design features that standard products cannot provide. This is especially important in applications where resistance to corrosion, heat, or wear is critical.Q: Where are your equipment fabrication services available?

A: We are based in India and supply our custom fabricated equipment to clients across the country and internationally. Our services cater to a broad spectrum of construction and industrial sectors.Q: What is the fabrication process for custom made equipment?

A: Our fabrication process involves precise cutting, welding, machining, and bending of selected materials. Each step is carefully controlled to ensure dimensional accuracy and high-quality results. Protective coatings and surface finishes are then applied to enhance durability and performance.Q: How does surface finishing benefit the fabricated equipment?

A: Surface finishing options such as polishing, brushing, or sandblasting enhance both the appearance and protection level of the equipment. They provide improved resistance against environmental factors and contribute to easier maintenance and longer operational life.Q: What are the main benefits of choosing your fabrication services?

A: By choosing our custom equipment fabrication, you benefit from tailored solutions, advanced material and protection selection, rigorous quality control, and reliable service from a leading exporter, manufacturer, and supplier in India. Our products are designed to deliver superior performance and durability in demanding applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heavy Fabrication Works Category

Structural Fabrication Work

Price 175 INR / Kilograms

Minimum Order Quantity : 10 Metric Tons

Size : As per requirement

Protection Level : Corrosion Resistant, Weather Resistant (

Fabrication Product : Structural Fabrication Work

Usage & Applications : Construction, Industrial

Heavy Fabrication Work

Price 500000 INR / Piece

Minimum Order Quantity : 1 Piece

Size : 10 x5

Protection Level : Corrosion Resistant, Weatherproof

Fabrication Product : Heavy Fabrication Work

Usage & Applications : Construction, Industrial

Silos and Tank Fabrication

Minimum Order Quantity : 1 Plant

Size : As per requirement

Protection Level : Corrosion Resistant, Weather Resistant, Pressure Resistant

Fabrication Product : Silos and Tank Fabrication

Usage & Applications : Food Processing, Chemical Industry, Water Treatment

Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese